Pellet feed offers balanced nutrition, easy digestion, and reduced waste. High-temperature processing further enhances feed conversion and extends shelf life.

For these benefits, more users are turning to pellet feed production lines both for home farming and commercial use.

.webp)

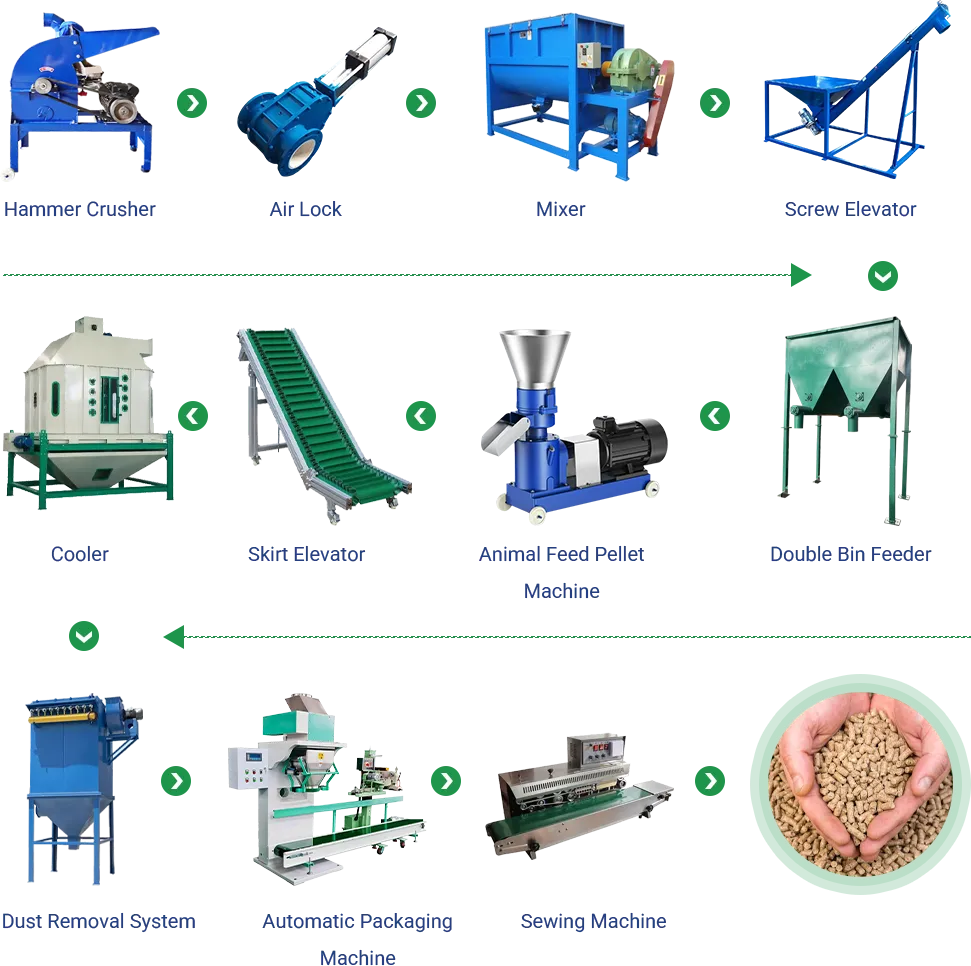

Equipment Used in Feed Pellet Production Line

Following are common machines used in feed pellet production lines, specific equipment can vary based on your needs.

- Hammer Crusher: Crushes materials into powder size.

- Air Lock: Controls material feeding speed, isolates airflow, and prevents dust backflow.

- Mixer: Mixes different ingredients, premixes, and oils.

- Screw Elevator: Transports materials from one machine to the next.

- Double Bin Feeder: Divides materials into two different feed pellet machines.

- Animal Feed Pellet Machine: Converts materials into feed pellets as required by customers.

- Skirt Elevator: Transports materials from one device to another.

- Cooler: Rapidly cools down particles to prevent moisture and breakage, making storage and transport easier.

- Dust Removal System: Removes dust and screens out impurities, leaving intact pellets for packaging.

- Automatic Packaging Machine: Packs the finished pellets into bags.

- Sewing Machine: Seals the bags to complete the packaging.

Below, we introduce 4 popular and practical feed pellet production lines to help you choose the right system for your goals.

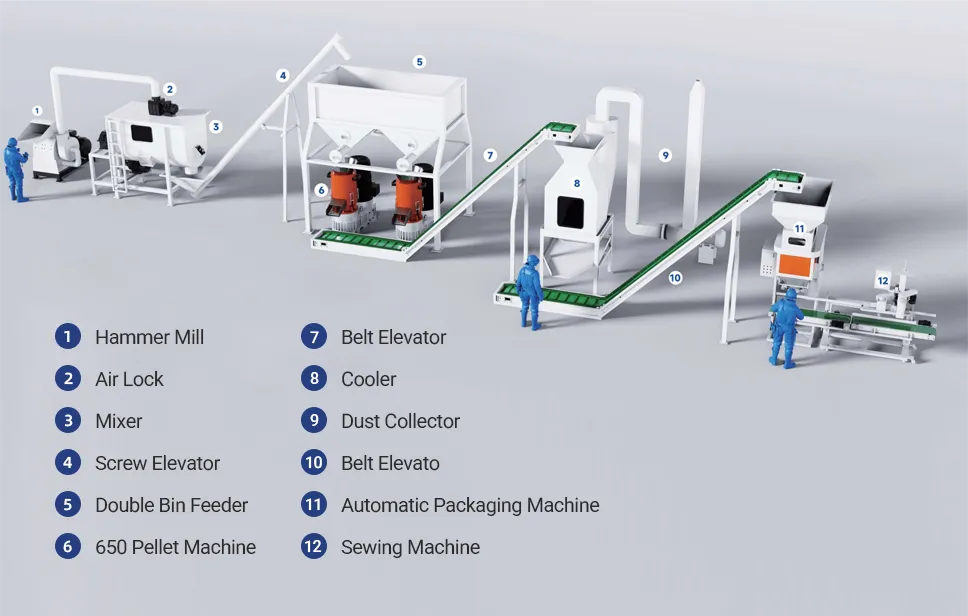

4-6t/h High Efficiency Feed Pellet Machine Production Line

Ideal for large and medium-sized feed processing plants seeking high output, stable efficiency, and energy-saving operations. Recommended footprint: 250–350 m²

Flow Chart

Hammer Mill → Air Lock → Mixer → Screw Elevator → Double Bin Feeder → 650 Pellet Machine → Belt Elevator → Cooler → Dust Collector → Belt Elevator → Automatic Packaging Machine → Sewing Machine → Automatic Control Center

Advantages of the Feed Pellet Line

- High output and efficiency, suitable for large-scale production.

- Energy-saving and environmentally friendly, reducing long-term operating costs.

- High level of automation, reducing manual intervention and enhancing production stability.

Machine Specifications

| Model Name | Power (KW) | QTY |

| 1000 Hammer Crusher | 45-55 | 1 |

| Air Lock | 1 | |

| Mixing Machine | 11 | 1 |

| Screw Conveyor | 5.5 | 1 |

| Uniform Feeder | 4.4 | 1 |

| 650 Feed Pellet Machine | 90-120 | 2 |

1.5-2 t/h Standard Poultry Feed Production Line

Perfect for medium-scale feed mills with moderate production needs, offering reliable performance and cost-effective operation. Recommended footprint: 150–200 m²

Flow Chart

Hammer Mill → Mixer → Screw Conveyor → Double Bin Feeder → Feed Pellet Mill → Bucket Elevator → Dust Collection System → Bucket Elevator → Automatic Packaging Machine

Advantages of the Feed Pellet Line

- Cost-effective for enterprises with limited budgets.

- High stability to meet daily production requirements.

- Simple installation and easy maintenance, operable by only 2-3 people.

Machine Specifications

| Model Name | Power(KW) | QTY |

| 750 Hammer Crusher | 22-30 | 1 |

| Mixing Machine | 7.5 | 1 |

| 165 Screw Conveyor | 4 | 1 |

| Uniform Feeder | 2.2 | 1 |

| 400 Feed Pellet Mill | 37 | 2 |

| Skirt Belt Elevator | 2.2 | 2 |

| Vibration Dust Removal System | 4 | 1 |

| Automatic Weighing and Packaging Machine | 1 | 1 |

| Control Center | 2 |

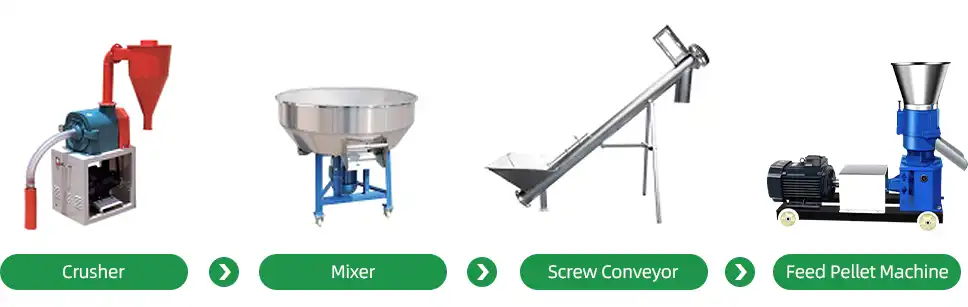

500-650 KG/H Simple Animal Feed Production Line

Designed for small feed processing plants or startups, offering a simple solution with moderate output and cost-effective performance. Recommended footprint: 60–100 m²

Flow Chart

Crusher → Mixer → Screw Conveyor → Feed Pellet Machine

Advantages of the Feed Pellet Line

- Low cost, ideal for small businesses with limited budgets.

- Easy to install, operate, and maintain.

- Meets daily production needs with high cost-effectiveness.

Machine Specifications

| Model Name | Capacity(Kg/h) | Power(KW) | QTY |

| 400 Hammer Crusher | 500-600 | 7.5-11 | 1 |

| Mixing Machine | 50 | 7.5 | 1 |

| Screw Conveyor | 200-300 | 2.2 | 1 |

| KD-300 Pellet Mill | 500-700 | 22 | 1 |

200-300 KG/H Small Type Feed Pellet Machine Production Line

Suitable for small farms, household breeders, and startup feed processing businesses with low feed pellet production requirements. Recommended footprint: 30–50 m².

Flow Chart

Hammer Mill Crusher → Feed Pellet Machine

Advantages of the Feed Pellet Line

- Easy to operate, ideal for users without technical expertise.

- Low cost, high cost-effectiveness for budget-conscious customers.

- Compact, space-saving, and easy to install.

- Upgradable for future growth.

Machine Specifications

| Model Name | Capacity | Power(KW) | QTY |

| Hammer Mill and Crusher | 500KG/batch | 7.5+3kw | 1 |

| Pellet Machine | 200-300 kg/h | 7.5 | 1 |

Partner with Kawise

Choosing the right feed pellet production line requires considering not only equipment quality, configuration, and output but also reliable service and after-sales support.

Kawise Machinery with more than 16 years’ experience in pellet mill production and trusted by customers in over 30 countries across Asia, Africa, Europe, and North America.

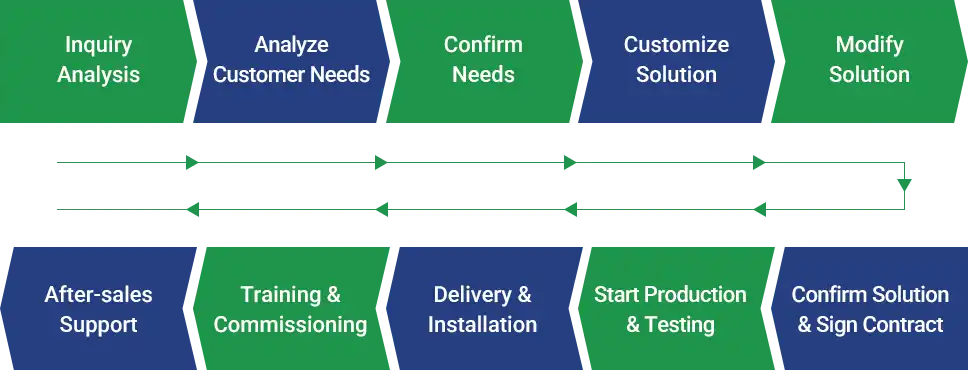

About Our Service

We are dedicated to providing efficient and tailored feed pellet production solutions that precisely meet each customer’s specific needs.

From professional equipment selection and production line design to installation guidance, training, and after-sales support, we provide full-service experience to help you quickly build and launch your feed production line.

Service Process:

Inquiry Analysis → Analyze Customer Needs → Confirm Needs → Customize Solution → Modify Solution → Confirm Solution & Sign Contract → Start Production & Testing → Delivery & Installation → Training & Commissioning → After-sales Support

Not sure which animal feed production line is suitable for you? Contact us today for a free customized solution.

Feed Pellet Machine

Feed Pellet Machine- Capacity 80–1200 kg/h, pellets size 2.5-8mm fulfill different requirements.

- For small scal pellet production like small farm, poultry breeders,etc.

- Multiple power options (electric, diesel, PTO) for any environment.

- From the manufacturer give customers competitive price.