With shrimp farming expanding rapidly, feed producers are grappling with higher production costs and growing concerns over aquaculture-related diseases. Traditional production methods often fail to ensure feed hygiene or pellet stability in water and tend to be inefficient.

The KAWISE shrimp feed pellet production line provides a fully automated shrimp feed production process—from raw ingredients to final pellets. It uses high-temperature and high-pressure processing to eliminate pathogens and improve feed quality. As a result, the production process is cleaner, safer, and significantly more efficient.

Shrimp Feed Production Line Overview

- Raw materials: Fish meal, soybean meal, peanut meal, shrimp meal, salmon meal, feed yeast, flour, fish oil, soybean lecithin, feed flavoring, and more.

- Feed types: Suitable for producing feed for various shrimp species, including grass shrimp, redtail shrimp, king shrimp, freshwater shrimp, and whiteleg shrimp.

- Pellet size: 0.5 mm to 3 mm, meeting the nutritional requirements of shrimp at various growth stages.

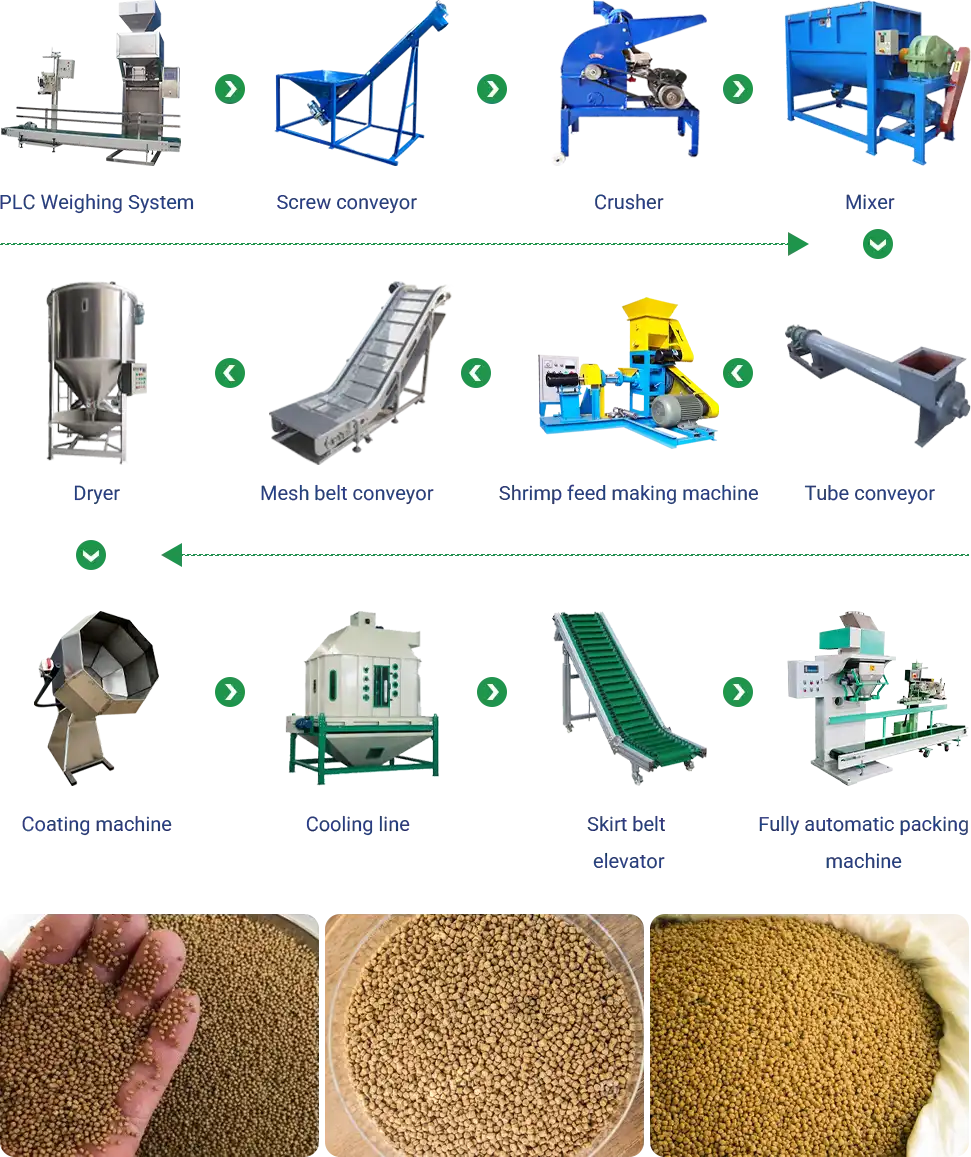

Equipment Included in the Production Line

- PLC Weighing System – Weighs and batches various raw materials according to the set formula.

- Screw conveyor – Transfers materials between machines while preventing leakage and dust emission.

- Crusher – Grinds raw materials into fine powder. Customizable sieve sizes; final particle size ranges from 0.5 mm to 20 mm.

- Mixer – Powered by a reducer motor directly connected to the paddles. Efficiently mixes flour-like materials inside the chamber.

- Tube conveyor – Uses chain-driven discs in a sealed pipeline for dust-free and damage-free material transport.

- Shrimp feed making machine – Applies high temperature and pressure to gelatinize starch and denature proteins, producing either floating or sinking pellets.

- Mesh belt conveyor – Transports extruded pellets to the dryer, helping maintain a smooth and efficient workflow.

- Dryer – Reduces moisture in the pellets to prevent mold, prepare for oil spraying, and extend shelf life.

- Coating machine – Sprays liquid or oil onto the feed to increase fat content, improve palatability, and enhance water resistance.

- Cooling line – Cools and transfers the pellets after coating, before packaging.

- Skirt belt elevator – Gently lifts coated pellets to the packing machine with minimal breakage; ideal for larger pellets.

- Fully automatic packing machine – Integrates weighing, bagging, sealing, and labeling for precise, ready-for-storage packaging.

If you're looking to produce different types of feed or have specific processing requirements, feel free to get in touch with us.

Types of Shrimp Feed Pellet Production Lines

Based on practical project experience, KAWISE has identified three shrimp feed production line configurations that are widely adopted by our clients.

1–1.5T/D Shrimp Feed Production Line

This production line is ideal for small-scale shrimp feed manufacturing and is especially suitable for startups. It features low investment cost, high flexibility, and easy operation. This makes it a great choice for producing small batches of shrimp feed on a daily basis.

| Equipment | Power | Capacity | Quantity |

| Crusher | 4 kW | 200–300 kg/h | 1 |

| Mixer | 7.5 kW | 250 kg/batch | 1 |

| Tube Conveyor | 2.2 kW | 200–300 kg/h | 1 |

| Extruder | 15 kW | 100–150 kg/h | 1 |

| Mesh Belt Conveyor | 1.5 kW | 200–250 kg/h | 1 |

| Stainless Steel Dryer | 7 kW | 75 kg/batch | 1 |

| Oil Sprayer | 1.5 kW | 50 kg/batch | 1 |

| Skirt Belt Elevator (L: 5.5 m, H: 2.7 m) | 2.2 kW | 500 kg/h | 1 |

| Automatic Weighing & Sealing Machine | 1.5 kW | – | 1 |

|

Total Power: 42.4 kW Hourly Output: 100–150 kg/h |

Estimated Price: $10,000–$13,500 | ||

1.5–2T/D Shrimp Feed Pellet Production Line

This production line offers higher automation and improved efficiency. It's especially suitable for small local feed plants and emerging feed brands that are just starting out. It helps build a solid foundation for small-scale, stable production.

| Equipment | Power | Capacity | Quantity |

| Crusher | 4.5 kW | 200–300 kg/h | 1 |

| Screw Feeder | 2.2 kW | 500 kg/h | 1 |

| Mixer | 7.5 kW | 50 kg/batch | 1 |

| Tube Conveyor | 2.2 kW | 200–300 kg/h | 1 |

| Extruder | 18.5 kW | 150–200 kg/h | 1 |

| Mesh Belt Conveyor | 1.5 kW | 200–250 kg/h | 1 |

| Dryer | 7 kW | 75 kg/batch | 1 |

| Cooling Line | 1.1 kW | – | 1 |

| Oil Sprayer | 1.5 kW | 50 kg/batch | 1 |

| Skirt Belt Elevator (L: 5.5 m, H: 2.7 m) | 2.2 kW | 500 kg/h | 1 |

| Automatic Weighing & Sealing Machine | 1.5 kW | – | 1 |

|

Total Power: 49.7 kW Hourly Output: 150–200 kg/h |

Estimated Price: $17,400–$23,000 | ||

2–4T/D Shrimp Feed Production Line

This fully automated line is ideal for small local feed plants that already have an established market presence. It’s also a great fit for emerging feed brands looking to scale up. It offers a flexible, efficient solution while ensuring high feed quality and consistency.

| Section & Power Consumption | Included Machines | Quantity |

|

PLC Weighing System (1.5 kW) |

Batching scale (with support frame) | 1 |

| Load cells | 4 | |

| PLC control screen | 1 | |

|

Crushing, Mixing & Liquid Addition System (22.5 kW) |

Screw conveyor | 1 |

| Hammer mill | 1 | |

| Mixer | 1 | |

| Liquid dosing machine (automatically adds water, oil, etc. into the mixer) | 1 | |

|

Extrusion System (39.8 kW) |

Screw conveyor | 1 |

| Single-screw extruder | 1 | |

|

Drying System (47.8 kW) |

Air blower (provides negative pressure airflow for material transport) | 1 |

| Collector (separates air and feed material, collects pellets) | 1 | |

| Airlock (controls flow and prevents backflow of air) | 1 | |

| Multi-layer mesh belt dryer | 1 | |

| Cooling & Screening System (10.15 kW) | Air blower, collector, airlock | 1 |

| Cooler | 1 | |

| Vibrating screen (removes fines and broken pellets before packaging) | 1 | |

|

Coating System (5.57 kW) |

Air blower, collector, airlock | 1 |

| Coating machine | 1 | |

| Heat sealer | 1 | |

|

Total Power: 127.32 kW Hourly Output: 200–400 kg/h |

Estimated Price: $51,080–$60,000 | |

How to Choose the Right Shrimp Feed Production Line?

Choosing the right production line is a key step in launching your shrimp feed business. To ensure production efficiency and a solid return on investment, consider the following factors when making your decision:

- Define your production capacity based on your actual needs.

- Choose the right processing methods and equipment to match your feed type.

- Select a control system that fits your level of automation and operational goals.

- Plan the factory layout and structural design to support smooth workflow.

- Design the production flow carefully to ensure each step connects efficiently.

Design and equipment configurations may vary based on raw materials, processing methods, feed formulas, plant size, and local regulations.

If you’re looking to build a high-efficiency, high-quality shrimp feed production line, feel free to contact our engineering team. We’re here to help you find the solution that fits your needs.

Why Choose KAWISE Production Lines?

As a professional pellet machine manufacturer, KAWISE focuses on delivering efficient and reliable feed crushing and pelleting solutions to customers worldwide. Here’s what sets us apart:

- Our factory is fully equipped for punching, metal processing, painting, and electrical control. With advanced equipment, skilled craftsmanship, and precise quality control, we provide high-quality service to customers at home and abroad.

- We offer free feed formulas and die molds, along with professional technical support and custom services to help improve feed quality and production efficiency.

- All machines and production lines can be customized to meet specific needs. We provide multiple feed production solutions with detailed comparisons to help clients choose the most suitable option.

- We follow a standardized delivery process: Order review → Factory inspection → Packing list check → Secure packaging → Shipment. This ensures safe and damage-free delivery.

- Based on your needs, KAWISE engineers will provide on-site guidance for infrastructure preparation, equipment installation, commissioning, and test runs.

- Our technical team supports every stage of your project—from initial consultation and site inspection to sample analysis, solution design, installation, and maintenance—to ensure smooth project execution.

Case Showcase

700 Tons/Year Shrimp Feed Pellet Production Line

Country: Vietnam

Client Name: Shrimp Feed Processing Plant

Completion Date: May 25, 2023

Capacity: 150–200 kg/h

Feed Size: 0.5–3 mm

Installation Period: 20 days

Client Type: Local feed processing plant

This small feed plant in Vietnam mainly supplies shrimp feed to local farmers. In the past, they relied on traditional production methods such as manual mixing and sun drying. The pellets would easily break apart once in the water, which affected feeding results. Mold changes were inconvenient, and the overall operation was complex and inefficient.

As local farmers began demanding higher feed quality, the client decided to upgrade their equipment to improve product stability and production efficiency.

They ultimately chose to install KAWISE’s 1.5–2T/D shrimp feed pellet production line. After commissioning, the pellet stability in water improved significantly — they could soak for hours without disintegrating. This made feeding more consistent and reduced waste. Pellet size could be easily adjusted between 0.5 mm and 3 mm to meet the needs of shrimp at different growth stages.

The client noticed a clear improvement in both the quality and water stability of the shrimp food pellets. More farmers came back for repeat orders, and their annual output has stabilized at around 700 tons—with demand still growing.

1,400 Tons/Year Shrimp Feed Pellet Production Line

Country: Ecuador

Client Name: Feed Processing Plant

Completion Date: September 1, 2024

Capacity: 200–400 kg/h

Feed Size: 0.5–3 mm

Installation Period: 30 days

Client Type: Existing feed factory expanding into shrimp feed production

This feed plant in Ecuador originally specialized in poultry and livestock feed. As shrimp farming gained popularity, they saw the potential in aquaculture and decided to expand into shrimp feed production.

With no prior experience in this field, they needed a simple, reliable system to start small. KAWISE recommended the 2–4T/D shrimp feed pellet production line, which fit their needs for flexibility, quality, and ease of use.

Our team supported the full installation and trained operators on site. After launching, the pellets performed well—offering adjustable sizes (0.5–3 mm), strong water stability, and good extrusion. The client shared smooth operation and positive feedback from local farmers. They’re now considering a higher-capacity upgrade.

Your production needs are unique. Whether you're planning to build a new line or upgrade an existing one, we can provide a fully customized solution tailored to your goals.

If you have any questions about shrimp feed production line configurations, pricing, or technical options, feel free to reach out. Our team is here to offer expert advice and detailed support.