In fish farming and feed production, two things matter most: quality and cost. As raw material prices rise and standards get stricter, your equipment's performance becomes key to profitability.

That's why an efficient, reliable, and flexible production line is essential.

KAWISE offers a full solution-from raw material processing to final pellet shaping. We provide customized setups that help you cut costs and improve feed quality in one go.

Advantages of Our Fish Feed Production Line

- Consistent Quality: The production line ensures every pellet is uniform. Consistent pellets help fish grow healthier and make your farm more efficient.

- Cost Efficiency: The automated design helps reduce costs compared to manual feed production.

- Increased Profitability: Boost production capacity and achieve higher profits with a streamlined process.

- Easy Operation: The highly automated system reduces labor needs. Just 2–3 staff members can run and manage the entire line.

Fish Feed Pellet Line Overview

Ingredients

The production line can handle a wide variety of ingredients.

These include protein sources like fish meal and meat and bone meal, energy supplements such as wheat and corn, minerals and vitamins like shell powder and bone meal, and additives such as shrimp meal and algae-based colorants.

Feed Types

Suitable for both floating fish pellets and sinking feed pellets for species like tilapia, trout, catfish, carp, and tropical ornamental fish.

Pellet Sizes

Pellet diameter ranges from 0.5 mm to 10 mm. You can switch molds easily to match feeding needs at different fish growth stages.

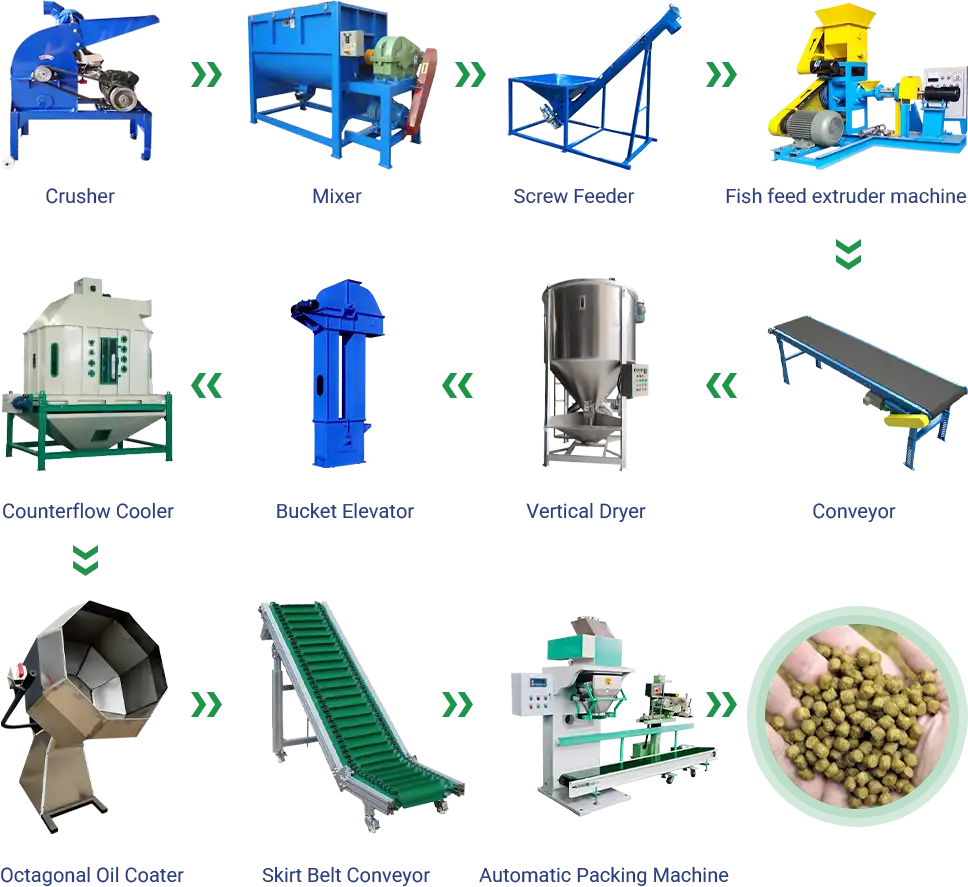

Equipment Included in the Production Line

- Crusher: Grinds raw materials like corn and soybean meal into fine powder for easier mixing and extrusion.

- Mixer: Blends powdered ingredients, additives, and water based on the feed formula to ensure even nutrition.

- Screw Feeder: Transfers the mixed powder to the extruder hopper in a sealed way to reduce dust and keep feeding stable.

- Fish feed extruder machine: Uses high temperature and pressure to compress and shape the material. During extrusion, starch is gelatinized and proteins are denatured, forming either floating fish pellets or sinking pellets.

- Conveyor: Moves the extruded pellets smoothly to the dryer. Prevents breakage and pile-up during transfer.

- Vertical Dryer: Uses hot air to dry the pellets. Its compact vertical design saves space and protects pellet shape.

- Bucket Elevator: Lifts the dried pellets vertically for the next step in the process.

- Counterflow Cooler: Uses reverse airflow to cool the pellets evenly, preventing deformation and improving storage stability.

- Octagonal Oil Coater: Sprays oil, vitamins, or flavor enhancers onto the pellets during rotation. Improves palatability with even coating.

- Skirt Belt Conveyor: Gently transfers coated pellets to the packing machine. Ideal for large-size pellets with less breakage.

- Automatic Packing Machine: Handles weighing, bagging, sealing, and labeling in one step. Supports fixed-quantity packaging and ready-for-storage output.

There are many different process setups depending on each customer's needs. This setup shows the standard process for fish feed pellet production.

If you're planning to make other types of feed or need a custom solution, feel free to contact us-we're happy to help.

Types of Fish Feed Pellet Production Lines

Through years of project experience, KAWISE has come to recommend three production line setups commonly chosen by our clients.

1.2–1.5 T/D Fish Feed Pellet Production Line

Ideal for startups or small-scale production. This line is affordable, easy to operate, and requires minimal investment.

| Machine | Power | Capacity | Qty |

| Crusher (Model 360) | 4.5 kW | – | 1 |

| Mixer | 3 kW | 25 kg/batch | 1 |

| Screw Feeder | 2.2 kW | 500 kg/h | 1 |

| Pellet Mill (Model 60) | 15 kW | 120–150 kg/h | 1 |

| Dryer | 4 kW | 75 kg/batch | 1 |

| Oil Coater (Model 800) | – | 25 kg/batch, 4–5 min/batch | 1 |

| Skirt Belt Conveyor (L 5.5 m, H 2.7 m) | 2.2 kW | 500 kg/h | 1 |

| Automatic Packing & Sealing Machine | 1.5 kW | – | 1 |

|

Total Power: 32.4 kW Hourly Output: 120–150 kg/h |

Estimated Price: $11,000 – $13,500 | ||

1.5–2 T/D Fish Feed Pellet Production Line

This setup is ideal for small feed processing plants or emerging aquaculture feed manufacturers. It includes an additional screw feeder and conveyor for improved efficiency. With higher power and output, this line offers better performance and more stable operation, making it perfect for small-scale production.

| Machine | Power | Capacity | Qty |

| Crusher (Model 360) | 4.5 kW | – | 1 |

| Screw Feeder | 2.2 kW | 500 kg/h | 1 |

| Mixer | 7.5 kW | 50 kg/batch | 1 |

| Screw Feeder (2nd unit) | 2.2 kW | 500 kg/h | 1 |

| Extruder (Model 70) | 18.5 kW | 150–200 kg/h | 1 |

| Conveyor | – | – | 1 |

| Dryer | 6 kW | Approx. 75 kg/batch | 1 |

| Oil Coater (Model 800) | – | 25 kg/batch, 4–5 min/batch | 1 |

| Skirt Belt Conveyor (L 5.5 m, H 2.7 m) | 2.2 kW | 500 kg/h | 1 |

| Automatic Packing & Sealing Machine | 1.5 kW | – | 1 |

|

Total Power: 44.6 kW Hourly Output: 150–200 kg/h |

Estimated Price: $16,100 – $18,800 | ||

2–2.5 T/D Fish Feed Pellet Production Line

With a daily output of around 2.5 tons, this production line features a clear workflow and a complete set of equipment. It's a great fit for medium-sized farms or feed plants looking for automated production and stable performance.

| Machine | Power | Capacity | Qty |

| Crusher (Model 360) | 4.5 kW | – | 1 |

| Screw Feeder | 2.2 kW | 500 kg/h | 1 |

| Mixer (75 kg capacity) | 7.5 kW | 75 kg/batch | 1 |

| Screw Feeder | 2.2 kW | 500 kg/h | 1 |

| Extruder (Model 80) | 22 kW | 200–250 kg/h | 1 |

| Conveyor | – | – | 1 |

| Dryer | 7 kW | Approx. 100 kg/batch | 1 |

| Bucket Elevator | – | – | 1 |

| Counterflow Cooler | – | – | 1 |

| Oil Coater (Model 1000) | – | 40 kg/batch, 4–5 min/batch | 1 |

| Skirt Belt Conveyor (L 5.5 m, H 2.7 m) | 2.2 kW | 500 kg/h | 1 |

| Automatic Packing & Sealing Machine | 1.5 kW | – | 1 |

|

Total Power: 49.1 kW Hourly Output: 200–250 kg/h |

Estimated Price: $19,500 – $23,000 | ||

If you have other needs, feel free to contact us. We're happy to tailor a solution that fits your exact needs. enquire now

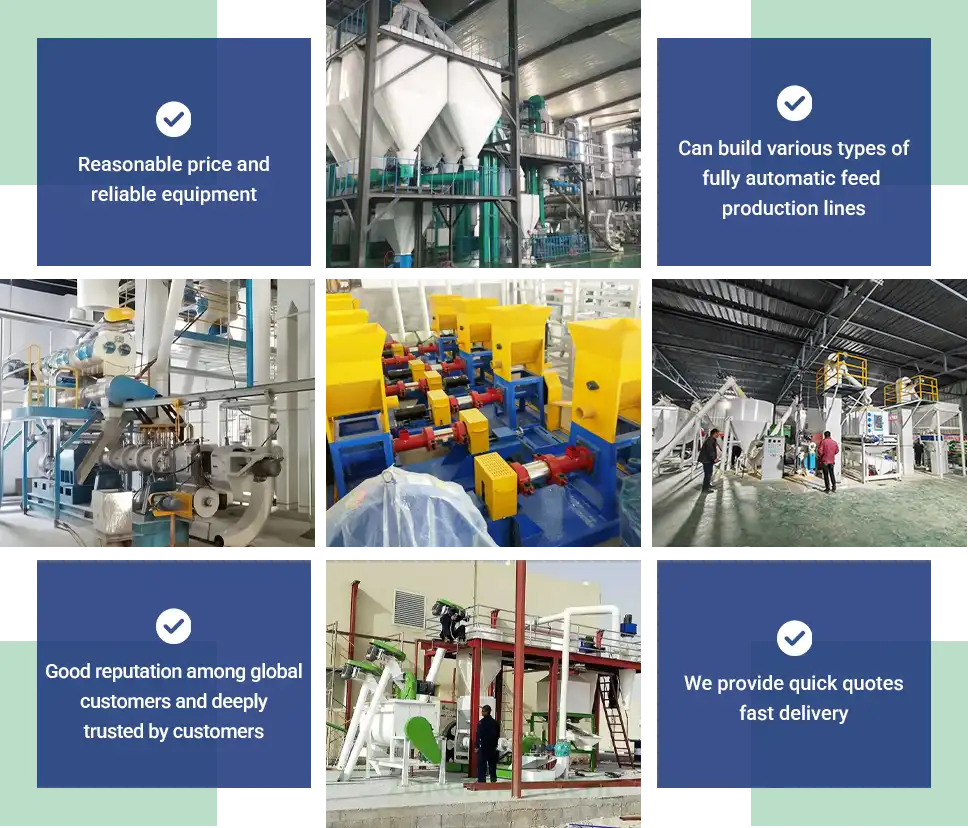

Why Choose Our Feed Production Line?

KAWISE is a professional pellet machine manufacturer based in China.

We're dedicated to providing high-quality feed grinding and pelleting equipment to customers around the world.

- We offer reliable machines at competitive prices, helping you reduce upfront investment and achieve faster payback.

- We can build fully automated feed production lines to meet different capacity needs.

- Our experienced technical experts deliver top-level process design and equipment support.

- We provide quick quotes, fast delivery, and respond to after-sales issues within 24 hours.

- On-site support from overseas engineers, free feed formulations, and aquaculture production solutions.

- One-stop service covering design, manufacturing, shipping, installation, training, and after-sales support.

- Trusted by customers around the world - our machines are already in use in Vietnam, Zambia, Indonesia, Nigeria, and more.

Application Case

550Tons/Year Fish Feed Pellet Production Line

Country: Nigeria

Client Name: Fish Feed Processing Plant

Completion Date: January 2, 2024

Capacity: 120–150 kg/h

Feed Size: 1–6 mm

Installation Period: 10 days

The client runs a small feed plant and mainly supplies feed to nearby fish farms. In the past, they relied on manual mixing and basic tools, which limited both efficiency and output. As local demand grew, this setup could no longer keep up. To improve productivity and expand supply, the client decided to invest in a compact and easy-to-operate fish feed pellet line.

After comparing several suppliers, they chose the full-line solution provided by KAWISE. The setup includes a crusher, mixer, screw feeder, extruder, dryer, oil coater, and packing machine. The layout is space-saving and user-friendly.

Since installation, output has been steady and pellet quality consistent. The client also saw a big boost in efficiency. Efficiency has improved significantly. They're now planning to upgrade or add a second line.

900 Tons/Year Fish Feed Pellet Production Line

Country: Zambia

Client Name: Fish Farm with Feed Line Expansion

Completion Date: January 2, 2025

Capacity: 2000–250 kg/h

Feed Size: 0.5–6 mm

Installation Period: 23 days

The client initially ran a small fish farm, mainly raising tilapia and carp. They used manual mixing with a basic extruder for feed processing. As the farm expanded, this setup could no longer meet the feed demand. Pellet quality was also inconsistent-especially in hot seasons when feed tended to clump and break apart, leading to high feed loss.

The client wanted to upgrade to a more stable and efficient production line. They needed a system that could replace the old setup, reduce labor, and supply extra feed pellets to nearby farms for added income.

After consulting with us, we recommended the 2–2.5 tons/day fish feed pellet line. KAWISE provided full installation guidance and on-site commissioning. After just one day of training, the workers were able to operate the line independently.

The client praised the pellet quality-floating well and wasting less feed. They currently supply feed to two nearby fish farms. To meet rising demand, they're evaluating the setup of a second production line.

Whether you're starting fresh or upgrading, we offer a full solution-from raw ingredients to final pellets.

If you'd like to learn more about fish feed production line setups, pricing, or customized plans, feel free to contact us. We'll recommend a setup that fits your production goals and investment plan.