In fish farming, feed often makes up over half the production cost. It has a direct impact on growth and profits - so feed quality is key. Learning how to make quality fish food pellets is one of the best ways to improve your farming results.

We'll walk you through the steps and techniques to help you make better feed and run more efficiently.

What Ingredients Are Used in Fish Feed Pellets?

Before you start making pellets feed, it's helpful to understand the ingredients involved.

| Category | Common Ingredients | Function |

| Protein | Fish meal, meat and bone meal, soybean meal, cottonseed meal | Supplies key amino acids for growth |

| Energy sources | Wheat, corn, rice, animal fat, vegetable oil | Provides energy and helps spare protein |

| Minerals & Vitamins | Fish meal, shell powder, bone meal, premixed vitamins | Boosts immunity with essential nutrients |

| Color enhancers | Synthetic astaxanthin, algae pigments, shrimp meal, chili pigment | Enhances color for appearance and market value |

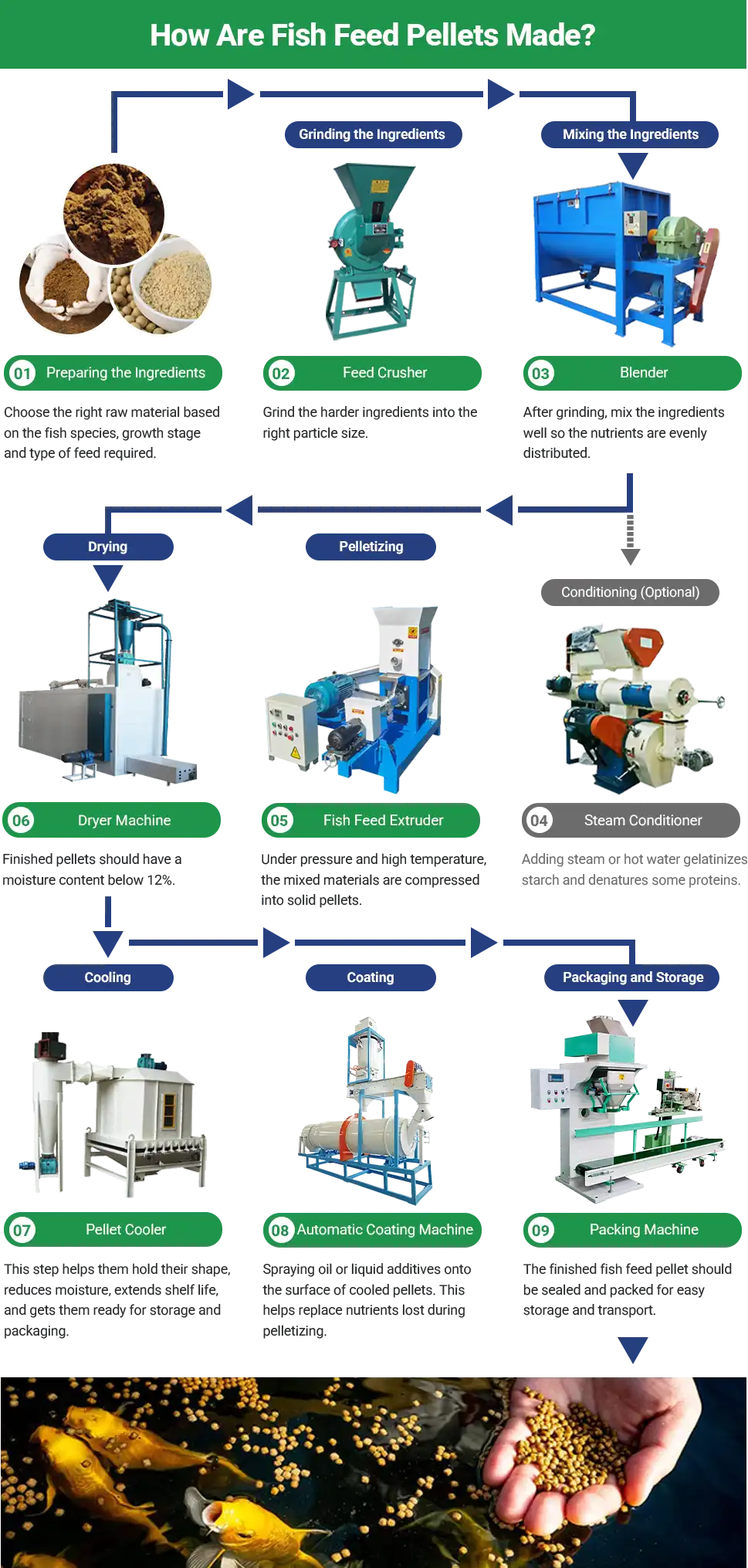

How Are Fish Feed Pellets Made?

1.Preparing the Ingredients

Start by selecting the right raw materials based on the type of fish, their growth stage, and the type of feed you need. (floating fishing pellets, sinking fish food pellets, or slow-sinking fish pellets.) Make sure everything is clean and safe to use.

The starch level in your mix affects buoyancy: around 10% starch works for sinking pellets, while 20% helps the feed float.

2.Grinding the Ingredients

After preparing the raw materials, grind the harder ingredients into the right particle size. This helps improve feed digestibility and palatability, and also enhances pellet quality.

You can use a stone mill or a manual crusher to break down larger pieces, though the process may be less efficient and consistent. For larger farms or feed plants, a feed grinder is recommended to improve both production efficiency and final feed quality.

3.Mixing the Ingredients

After grinding, mix the ingredients well so the nutrients are evenly distributed. A good mix helps improve feed quality and makes pelletizing more effective. What matters most is mixing evenly and preventing clumps or layers.

- Manual mixing

Start by adding the main ingredients, like corn and wheat, then mix in minerals, vitamins, and other additives. Stir from all sides toward the center for 5 to 10 minutes until everything is evenly mixed. If you're adding oil or water, spray it in gradually while stirring to avoid clumping.

- Machine (Blender) mixing

Start by dry-mixing the base ingredients and additives for 3 to 5 minutes. Then gradually add oil, fish oil, or other liquids, and keep mixing for another 5 to 10 minutes. Watch the mixing time-too short, and it won't mix evenly; too long, and the ingredients might separate.

(Note: Manual mixing is slower and less consistent, so it's not ideal for large-scale use.)

4.Conditioning (Optional)

Conditioning is a processing step where the mixed ingredients are treated with heat and moisture. Adding steam or hot water gelatinizes starch and denatures some proteins. This improves digestibility and helps the pellets form more easily.

Because conditioning equipment like steam conditioners can be expensive, this step is often skipped in basic fish feed production. But for premium feeds or when feed hygiene and consistency really matter, conditioning becomes a valuable part of the process.

(As an easier option, spray the mixed ingredients with hot water (above 80°C). Cover them and let them sit for a few minutes before pelletizing. This won't give the same results as steam conditioning, but it can still improve pellet quality.)

5.Pelletizing

Pelletizing is the key step in making fish feed pellet. Under pressure and high temperature, the mixed materials are compressed into solid pellets. This process improves feed texture, makes it easier to digest, and helps fish absorb nutrients more efficiently.

Fish pellet machines come in two main types based on how they apply pressure. You can choose the one that best fits your needs.

| Type | Features | Best for | Pellet Output |

| Dry-type fish feed extruder | Low cost, easy to operate, no steam boiler needed, simple to install. | Small to medium fish farms | Floating or sinking pellets |

| Wet-type fish feed extruder | Higher cost, comes with a conditioner and steam boiler, allows finer processing and better nutrition. | Large-scale or intensive operations | Floating or sinking pellets |

6.Drying

Drying is an important step in making fish food pellets. It helps reduce moisture so the pellets stay stable during storage and transport, and don't mold or spoil. Finished pellets should have a moisture content below 12%.

There are a few different ways to dry fish feed pellets.

- Dryer machine: A pellet-specific machine designed for drying in batches. Just load the pellets, set the temperature and time, and check them as they dry.

- Forced-air oven: Works for small batches but needs close monitoring. Adjust the heat to make sure the pellets dry evenly.

- Basic drying cabinet: If it doesn't have built-in airflow or moisture control, pair it with a hot air blower. Best for small-scale use.

- Solar dryer: Place it in direct sunlight and load the pellets inside. A good option for small-scale drying.

- Sun drying: Use a sunny, open space. Lay the pellets on plastic sheets, bamboo mats, or other clean surfaces to keep them off the ground. Best for small batches on clear, dry days.

7.Cooling

After drying, the pellets need to cool down. This step helps them hold their shape, reduces moisture, extends shelf life, and gets them ready for storage and packaging.

- Mechanical cooling

You can use a dedicated pellet cooler. Just feed in the hot pellets, the system uses forced air to quickly bring them down to room temperature. This stabilizes the pellets and lowers moisture to a safe level.

- Natural cooling

You can also spread the pellets out in a cool, dry area and let them air-cool naturally. But it's a slower method and may lead to less consistent results.

8.Coating

Coating means spraying oil or liquid additives onto the surface of cooled pellets. This helps replace nutrients lost during pelletizing and makes the feed more appealing to fish. Coating pellets after they cool helps keep oils, vitamins, and other heat-sensitive nutrients locked in.

You can use an automatic coating machine: just load the cooled pellets, add the liquid ingredients, and start the machine. It applies the coating evenly and works well for larger batches.

You can also spray by hand. Stir the pellets while spraying to ensure even coverage. This method costs less but takes more time and effort.

9.Packaging and Storage

Finally, the finished fish feed pellet should be sealed and packed for easy storage and transport.

For small-scale production, manual bagging is usually enough. For larger volumes, a packing machine is recommended. Simply pour the dried pellets into the feeder, set the target bag weight and sealing temperature, and the machine will automatically weigh, fill, and seal each bag.

Once packed, store the feed pellets in a dry, well-ventilated, and cool place. This helps prevent moisture damage and keeps the feed stable and safe over time.

The best fish feed pellet line for you depends on your budget, production goals, and scale. If you're not sure which setup is right for you, feel free to contact us. We'll gladly provide a free and professional recommendation.