Tired of frequent breakdowns, slow processing, uneven mixing, or single-product limitations? Many traditional lines just can’t keep up. Our easy-to-use, cost-effective dog food production line solves these problems, helping you boost output, reduce labor, and create high-quality dog food that meet diverse market needs.

6 Key Upgrades to Improve Your Product

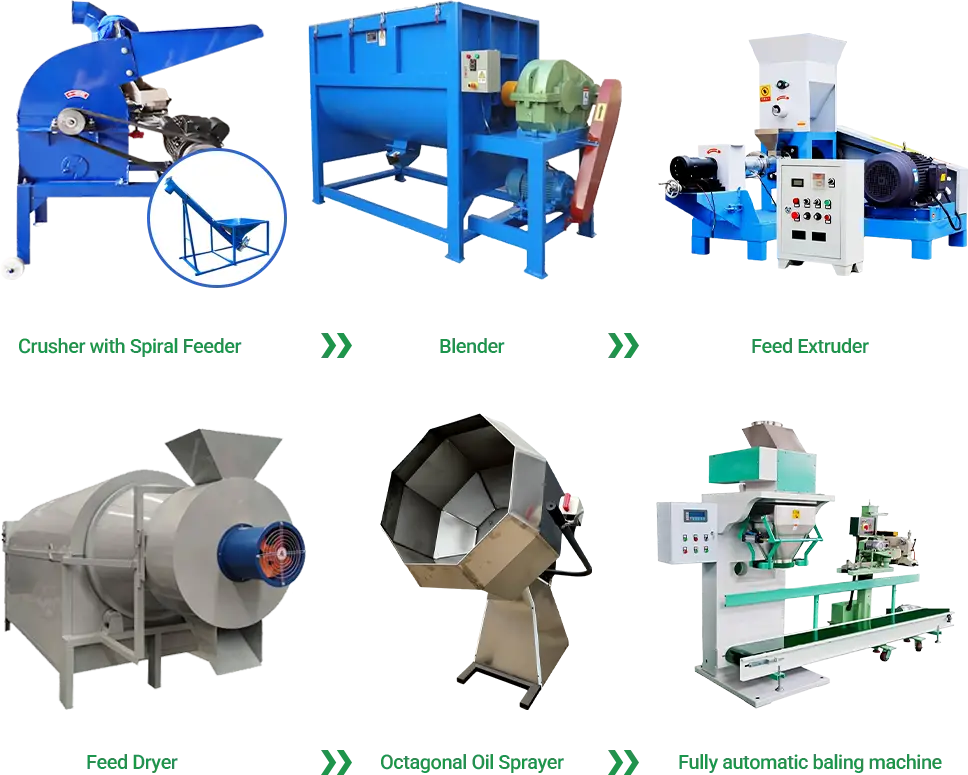

Our complete line covers everything from raw ingredients to final packaging. Here’s how it helps:

- Faster Raw Material Processing: A high-speed hammer mill with screw feeder cuts time and effort. You process more with less work.

- Better Mixing for Consistent Quality: Our mixers handle a wide range of ingredients and run automatically. Each batch stays stable and uniform.

- Flexible Extrusion for Different Dog Breeds: Adjust pellet size and shape easily. Make crispy, tasty kibble that fits every type of dog.

- Quick Drying for Longer Shelf Life: Precise moisture control keeps the kibble dry and prevents mold—ideal for storage and transport.

- Even Oil Coating for Better Taste: Uniform spraying boosts flavor and smell, making your product more appealing to pets and customers.

- Fully Automated Packaging: Weighing, filling, and sealing all in one step. You save labor and keep packaging clean and efficient.

Flexible Configurations to Fit Your Needs

Whether you’re starting small or upgrading the existing dog food production line, we offer flexible and low cost setups to match your capacity and budget. Below are our most popular configurations. (Custom options are also available for larger output.)

Capacity: 2.6–3.3 tons/day

| Equipment | Specification | Power (kW) |

| Hammer Mill | Model 360, High-speed crushing | 4.5 |

| Mixer | Batch capacity: 25 kg | 3 |

| Screw Feeder | Capacity: 500 kg/h | 2.2 |

| Dog food Extruder | Model 60, Output: 2.6–3.3 tons/day | 15 |

| Dryer | Batch drying: 75 kg | 6 |

| Octagonal Oil Coater | Capacity: 25 kg/batch, 4–5 mins/batch | 1.5 |

| Bucket Elevator | Length: 5.5m, Height: 2.7m | 2.2 |

| Automatic Packaging | Weighing + filling + sealing | 1.5 |

| Output: 120-150 kg/h (≈ 5,800-7,200 lbs/day) | ||

| Total Power:36 kW | ||

| Price Range:$12,000–13,000 | ||

Capacity: 3.3–4.4 tons/day

| Equipment | Specification | Power (kW) |

| Hammer Mill | Model 360 | 4.5 |

| Mixer | Batch capacity: 50 kg | 7.5 |

| Screw Feeder | Capacity: 500 kg/h | 2.2 |

| Dog food Extruder | Model 70, Output: 3.3–4.4 tons/day | 18.5 |

| Dryer | Batch drying: 75 kg | – |

| Octagonal Oil Coater | 25 kg/batch, 4–5 mins | 6 |

| Bucket Elevator | Length: 5.5m, Height: 2.7m | 2.2 |

| Automatic Packaging | Weighing + filling + sealing | 1.5 |

| Output: 120-150 kg/h (≈ 7,200-9,600 lbs/day) | ||

| Total Power:44 kW | ||

| Price Range:$14,000–16,000 | ||

Capacity: 4.4–5.5 tons/day

| Equipment | Specification | Power (kW) |

| Hammer Mill | Model 360 | 4.5 |

| Mixer | Batch capacity: 75 kg | 7.5 |

| Screw Feeder | Capacity: 500 kg/h | 2.2 |

| Dog food Extruder | Model 80, Output: 4.4–5.5 tons/day | 22 |

| Dryer | Batch drying: 100 kg | 7 |

| Octagonal Oil Coater | 40 kg/batch, 4–5 mins | – |

| Bucket Elevator | Length: 5.5m, Height: 2.7m | 2.2 |

| Automatic Packaging | Weighing + filling + sealing | 1.5 |

| Output: 120-150 kg/h (≈ 9,600-12,000 lbs/day) | ||

| Total Power:50 kW | ||

| Price Range:$16,000–18,000 | ||

Budget-Friendly Option

For users with a limited budget, we offer a low cost setup:

| Equipment | Specification | Power (kW) |

| Hammer Mill | Model 360 | 4.5 |

| Mixer | Batch capacity: 25 kg | 7.5 |

| Screw Feeder | Capacity: 500 kg/h | 2.2 |

| Dog food Extruder | Model 60, Output: 2.6–3.3 tons/day | 15 |

| Dryer | Max drying volume: 75 kg | 6 |

| Octagonal Oil Coater | Capacity: 25 kg/batch | 1.5 |

| Output: 120-150 kg/h (≈5,800–7,200 lbs/day) | ||

| Total Power:37 kW | ||

| Price Range:$5,700–7,700 | ||

This option maintains essential production functions with an output of 2.6–3.3 tons/day. It features a simpler design with lower automation, and manual packaging is required. A practical choice if you're looking to start small and stay efficient.

Note: The figures above are based on 22 hours of daily operation.

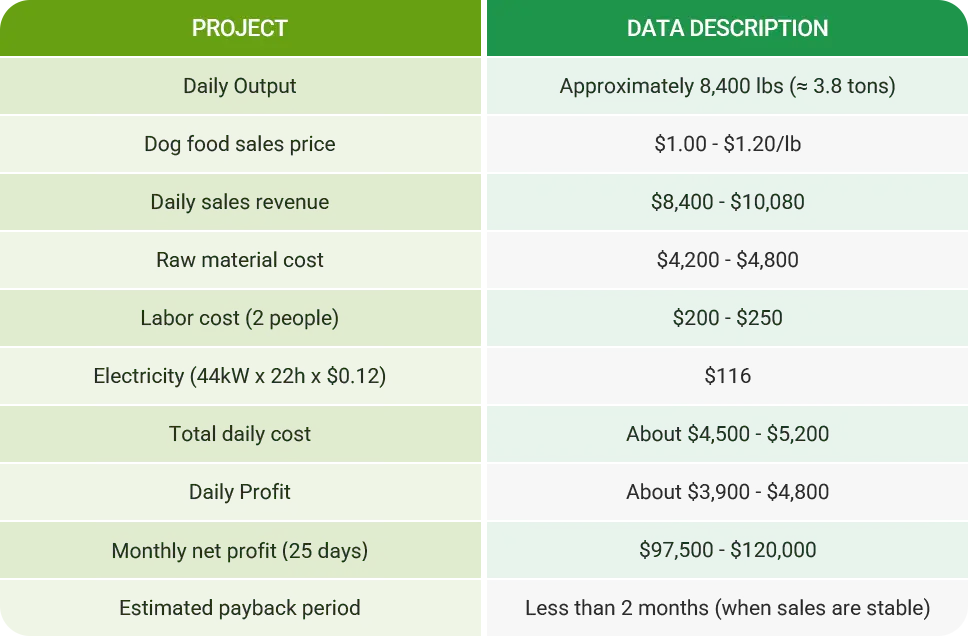

Return on Investment (Based on 150–200 kg/h Line)

- Production capacity: 150–200 kg/h

- Estimated daily output: 7,200–9,600 lbs/day (22 hours/day)

- Total equipment cost: ~$14,500

Note: Actual profits may vary depending on local market prices, raw material costs, and labor. The above is a conservative estimate for reference.

Why Choose Us?

We’re a trusted manufacturer with years of experience in dog food production equipment. Our production lines are used in many countries and loved by our customers. Here’s what we offer:

- One-stop solution – From raw materials to final packaging, we cover the full process.

- Custom pellet molds – Choose different shapes and sizes to meet market demand.

- Flexible configurations – We adapt to your space, budget, and production goals.

- Reliable equipment – Use durable components and well-known brands for key parts.

- Full support – Get installation guidance, training, and after-sales service from our team.

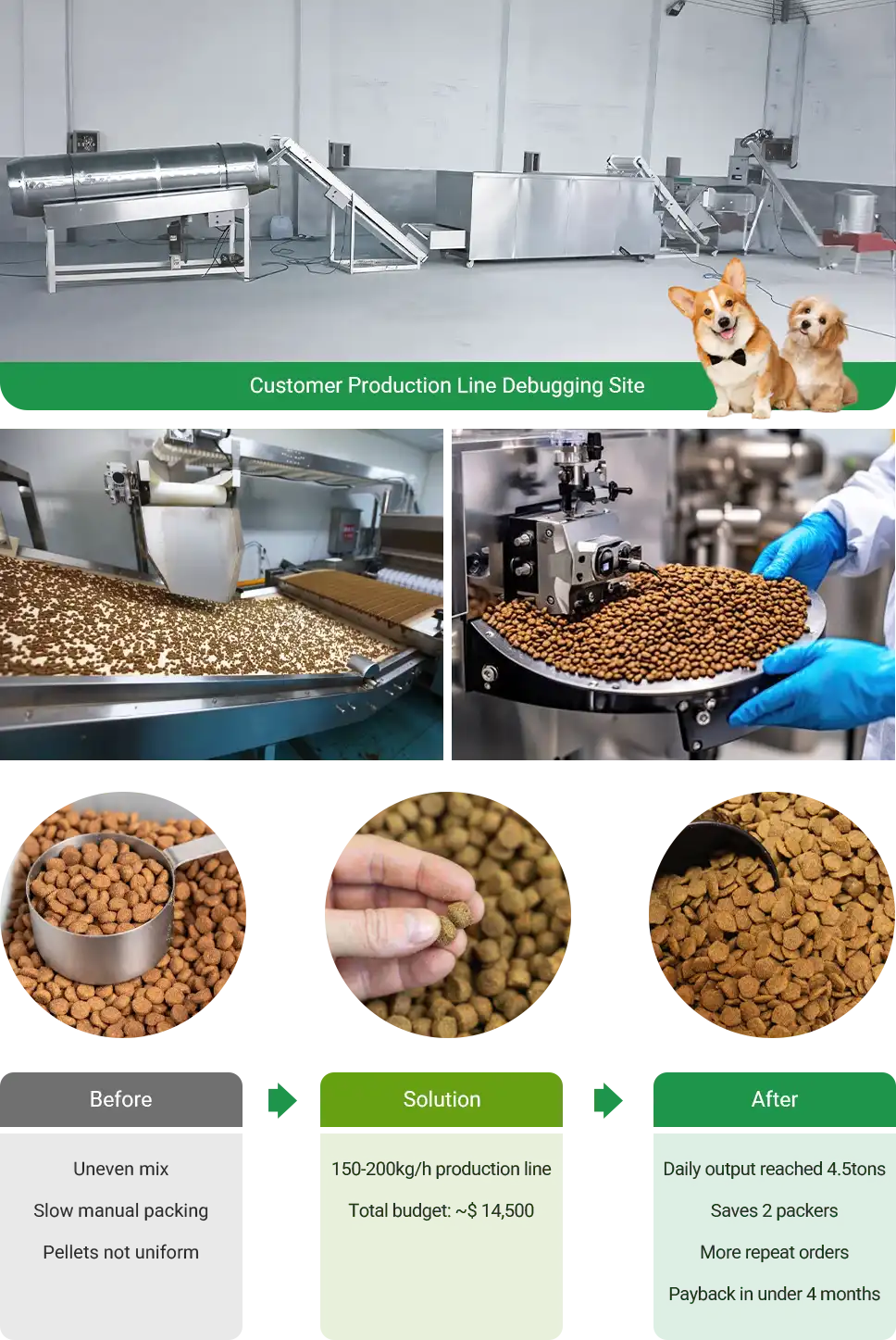

Customer Success Stories

From Manual Work to 4.5 Tons a Day — No Extra Hires Needed

📍 Texas, USA | Small dog food factory | 120㎡ space | 4-person team

From Zero Experience to Full Operation — All Run by Just Two People

📍 Ecuador | Couple-owned farm | 80㎡ workshop | No industrial experience

“We had a tight budget and zero experience. The machines were easy to operate, and video training helped a lot. Now just two of us handle everything. This system fits us perfectly!” — J.M.

Everyone’s needs are different—output, space, budget.

At Kawise, just tell us your plan or budget, and we’ll match you with the right solution—practical, efficient, and worth the investment.

Contact us today for a free quote and custom solution.

Pet Food Extruder Mill

Pet Food Extruder Mill- Produces feed for dogs, cats, fish, birds, and more.

- Change mold sizes to suit various pet breeds and species.

- User-friendly controls with clear settings.

- Allows for flexible ingredient mixing to meet nutritional needs.

- Continuous operation with consistent pellet quality.