Here is an efficient feed pellet machine solution for medium and small farms with production requirements of 100-200kg/h. You can choose the most suitable equipment according to your specific production needs. These small pellet machines save costs, and also efficiently produce the required feed pellets. The small pellet machine is a great investment choice.

Choose Equipment That Fits Your Production Needs

Here are the parameters of a small feed pellet machine suitable for production requirements of 100-200kg/h.

| Model | Power (kw) | Capacity (kg/h) | Roller | Die Hole (mm) | Total Weight (kg) |

| KD-150 | 4.5 | 80-130 | 2 | 2.5-8 | 115 |

| KD-160 | 4.5 | 130-180 | 3 | 2.5-8 | 120 |

| KD-210 | 7.5 | 200-300 | 2 or 3 | 2.5-8 | 190 |

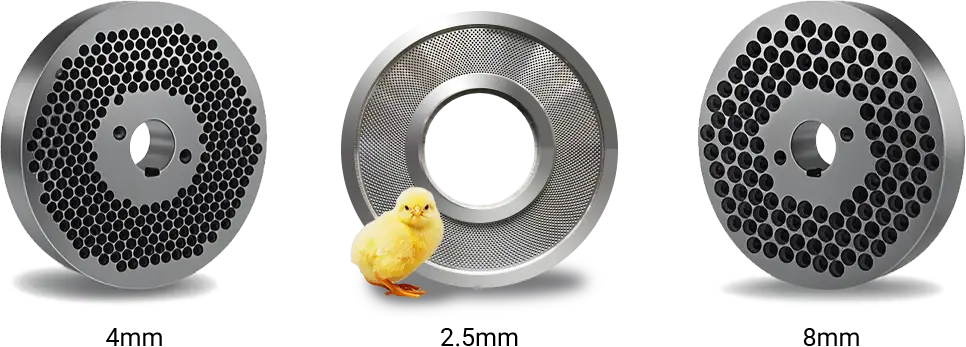

Small feed pellet machines are especially suitable for the output of 100-200Kg/h. This demand is not high for users. It feeds the raw material into a die and extrudes it into feed pellets under the pressure of rollers. You can adjust the particle size by changing the mold to suit different feed production needs.

Note: We also provide upgraded models. The standard and upgraded versions work the same. And the upgraded model has a fully enclosed motor, making it better for outdoor use.

Chicken Feed Pellet Size Recommendation

For chicken feed, the choice of mold diameter usually depends on the age and growth stage of the chicken. Different particle size can meet the needs of chickens at different stages:

|

Growth Stage |

Suitable Pellet Size |

Application |

|

Chick (0-3 weeks old) |

2-3mm |

Helps chicks easily consume and aids in digestion and absorption. |

|

Grower (4-10 weeks old)) |

3-4mm |

Help stimulate chewing and digestion, promoting bone and muscle development. |

|

Adult (over 10 weeks) |

4-6mm |

Increases feed density, reducing feed waste |

Our pellet machines come with die sizes ranging from 2.5mm to 8mm. You can select the die diameter according to the chicken’s growth stage for optimal feed quality.

Advantages of Small Feed Pellet Machine

- Efficient production to meet demand

- Uniform particles, quality assurance

- Easy to operate and maintain

- Energy saving and environmental protection, reduce costs

- Robust, stable and reliable

Precautions for Raw Material Selection

Chicken feed for small pellet machines should have pellets sized between 3-5mm and a humidity of 12%-15% for smooth molding. Mix raw materials evenly, maintain moderate oil content, and ensure they are free from impurities or harmful substances. This will help ensure feed quality and promote chicken health.

Recommended Chicken Feed Ingredients

|

Corn |

Provides essential energy, supports growth and egg production. |

|

Soybean Meal |

An important protein source aids muscle growth. |

|

Wheat |

Contains high-quality protein, vitamins, and minerals, easy to digest. |

|

Fish Meal |

Rich in amino acids and minerals promote growth. |

|

Vegetable Oil |

Supplies fats, increasing energy intake for the chickens. |

|

Bran |

Help maintain a healthy digestive system. |

|

Silage |

Provides fiber and vitamins needed by the chickens. |

|

Yeast |

Supports digestive and immune system health. |

|

Mineral Premix |

Help maintain bone health and overall well-being. |

|

Bone Meal |

A vital source of calcium, promoting effective eggshell formation in hens. |

Note: Before processing, crush the raw material to ensure smooth operation of the pellet machine. Also, mix all ingredients thoroughly to ensure the quality of pellets.

Small Pellet Machine

Small Pellet Machine- Small footprint, easy to move, meets various production needs

- Wide material adaptability, adjustable pellet size

- Simple operation, easy to learn

- Multiple power options for different environments

- Direct factory sale, cost-effective

Small feed pellet machines are cost-effective and efficient for small to medium-sized farms. They are easy to use, with adjustable die sizes for high-quality feed. Choose the right equipment and materials to improve feed quality and save costs.

Contact us for reliable machines and expert support.