Feed pellet machines process corn, soybean meal, and forage into pellets for livestock, poultry, pets, and fish. The capacity of different models ranges from 80 to 1200 kg/h, and the pellet sizes vary from 2.5 mm to 8 mm depending on the die size, meeting the feeding needs of various animals.

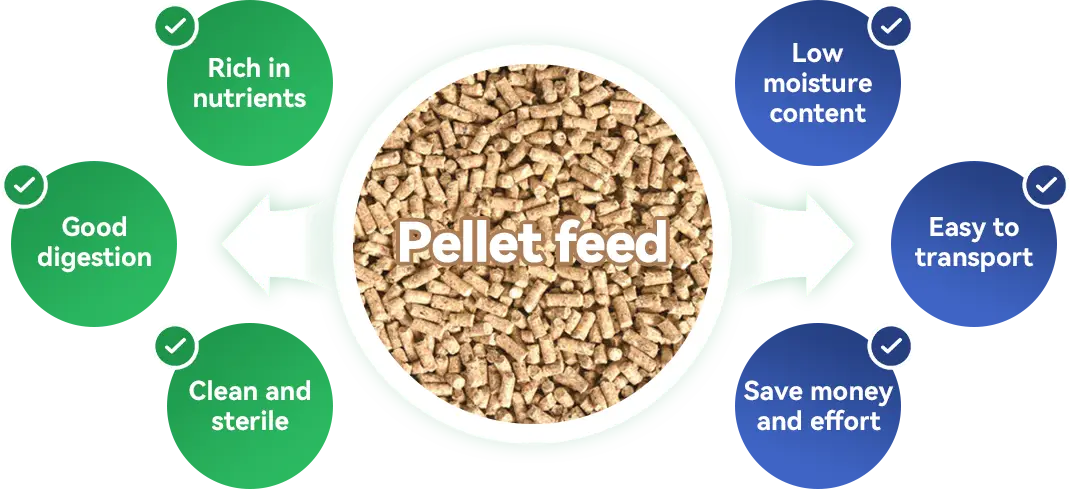

Why Feed Pellets for Animals

- Mix various raw materials can produce nutritious feed pellets and animals love to eat.

- Pellet feed is easier to digest and absorb, promoting animals' better growth.

- Compact shape and low moisture content, it is less prone to spoilage and easier to store and transport.

- High temperature pelleting process eliminates over 90% of harmful bacteria and parasites, improving animal health.

- Feeding pellets can reduce labor costs and helps maintain a cleaner, built more environmentally friendly farm.

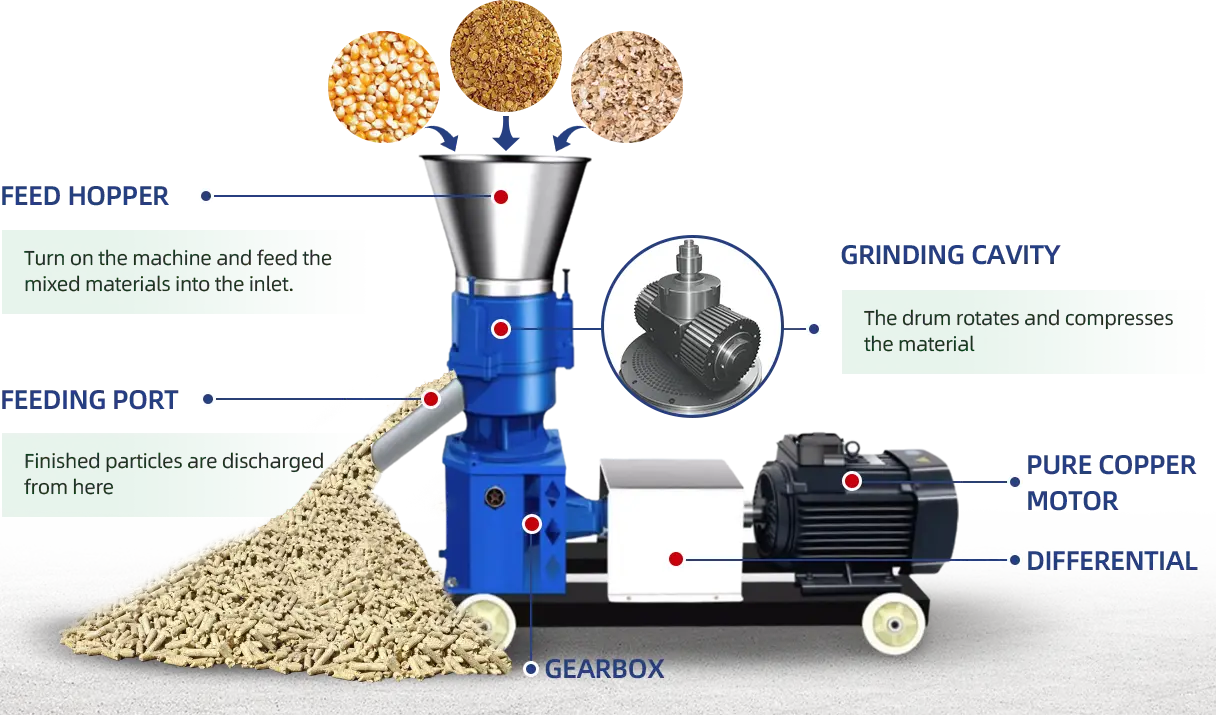

How to Use a Feed Pellet Mill in 4 Easy Steps

- Mix various raw materials.

- Turn on the machine and put the mixed materials into the inlet.

- The machine compresses the materials, and finished pellets exit through the outlet.

- Let pellets cool, then gather and store feed pellets properly.

Feed Pellet Machine Models & Capacities

We offer a variety of feed pellet machines to meet different needs, get more details in the parameter table.

| Model | Power (kw) | Capacity(kg/h) | Total Weight(kg) | Roller | Die Hole (mm) |

| KD-150 | 4.5 | 80-150 | 115 | 2 | 2.5-8 |

| KD-160 | 4.5 | 130-200 | 120 | 3 | 2.5-8 |

| KD-210 | 7.5 | 200-300 | 190 | 2 or 3 | 2.5-8 |

| KD-230 | 11 | 250-400 | 240 | 3 | 2.5-8 |

| KD-260 | 15 | 300-500 | 335 | 3 or 4 | 2.5-8 |

| KD-300 | 22 | 500-700 | 470 | 4 | 2.5-8 |

| KD-400 | 37 | 900-1200 | 810 | 4 | 2.5-8 |

Based on your local voltage and frequency requirements, we can offer motors suitable to your needs,not sure how to choose the suitable model, please feel free to contact us directly.

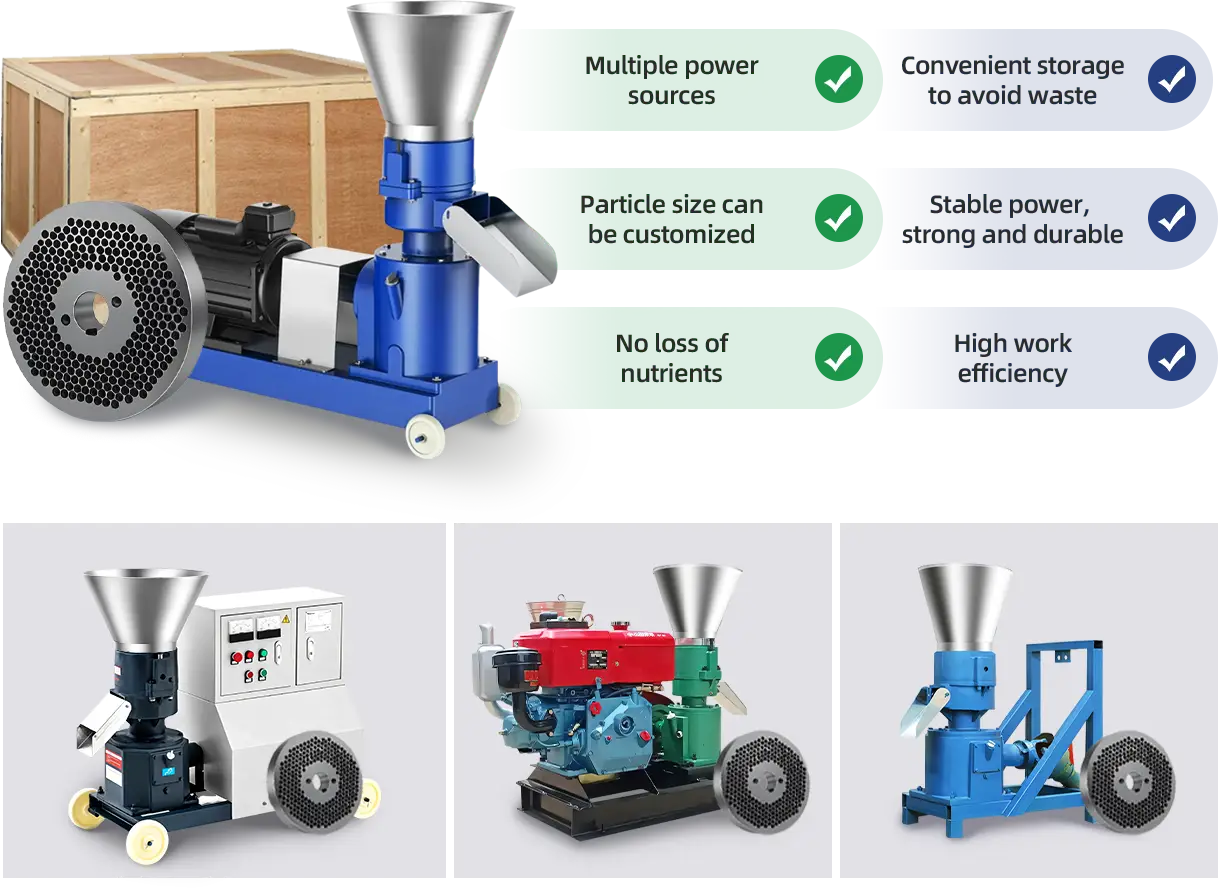

Why Choose Our Animal Feed Pellet Machines?

- Multiple Power Options: Available in electric, diesel, and PTO-driven models to meet different applications.

- Adjustable Pellet Size: pellets in sizes ranging from 2.5mm to 8mm to meet different animals' needs.

- Durable Components: Copper motors ensure steady power, while chromium-manganese steel die extends machine lifespan.

- Energy Efficient: Upgraded gears improve energy transfer, reduce power loss and boost efficiency.

- Competitive Prices: Direct from manufacturer with competitive price and reliable after-sale service.

Feed Pellet Machine Usage Tips

- New machines need a break-in grinding to smooth the die, helping produce pellets that are smooth and glossy.

- Clean the feed hopper before and after use to prevent clogging and ensure consistent pellet production.

- Keep the raw material's moisture content between 8-15%. (Tip: simple way to check: Take a handful of mixed material and squeeze it. Ideally, it should clump together but slowly fall apart when released. If it's too dry, pellets won't form properly. If it's too wet, they will be soft and may crumble).

- More tips, after purchase we provide a user manual to help you quickly master the machine's operation.

Contact us now with your requirements, and we'll get back to you within 24 hours.

.webp)