Fish feed pellet machine processes ingredients like wheat, corn, soybean meal, and other common feed materials. It produces pellets for tilapia, catfish, carp, shrimp, and other aquatic species.

Why Use a Fish Feed Extruder?

- Improves feed digestibility: The extrusion process breaks down starches and proteins, so fish can digest and absorb nutrients more easily.

- Supports healthier fish growth: High heat and pressure kill harmful bacteria, lowering disease risk and boosting survival rates.

- Enhances feeding efficiency: Extruded pellets stay intact in water longer, reducing waste and improving feed conversion ratios.

- Allows flexible, species-specific formulas: Extruders handle various ingredients and can meet the nutritional needs of different fish at every growth stage.

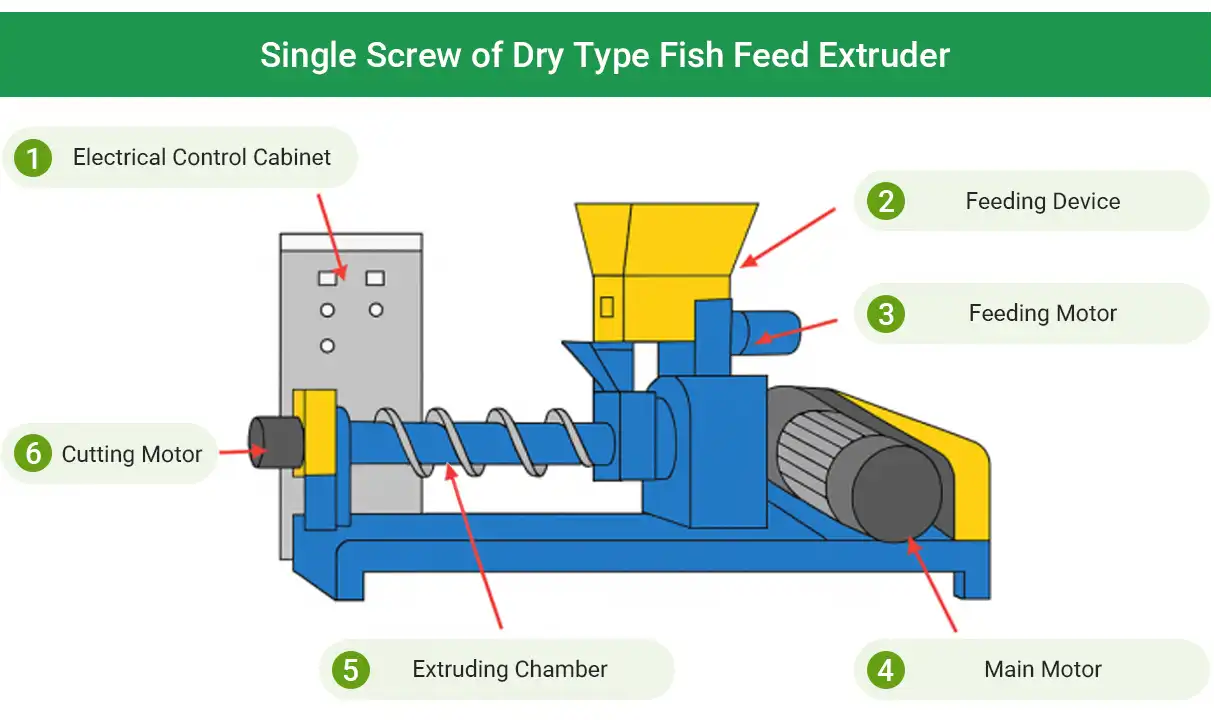

Key Components and Material Configuration

- Electrical Control Cabinet: Controls all functions of the machine from a single panel.

- Feeding Device: Made of stainless steel and designed to feed raw materials smoothly into the chamber.

- Feeding Motor: Drives the screw to ensure consistent and even feeding.

- Main Motor: Provides power to the screw for compressing and extruding the feed.

- Extruding Chamber: Built from wear-resistant alloy steel; this is where feed is compressed, cooked, and expanded under pressure.

- Cutting Motor: Drives the cutter to trim pellets to the desired length.

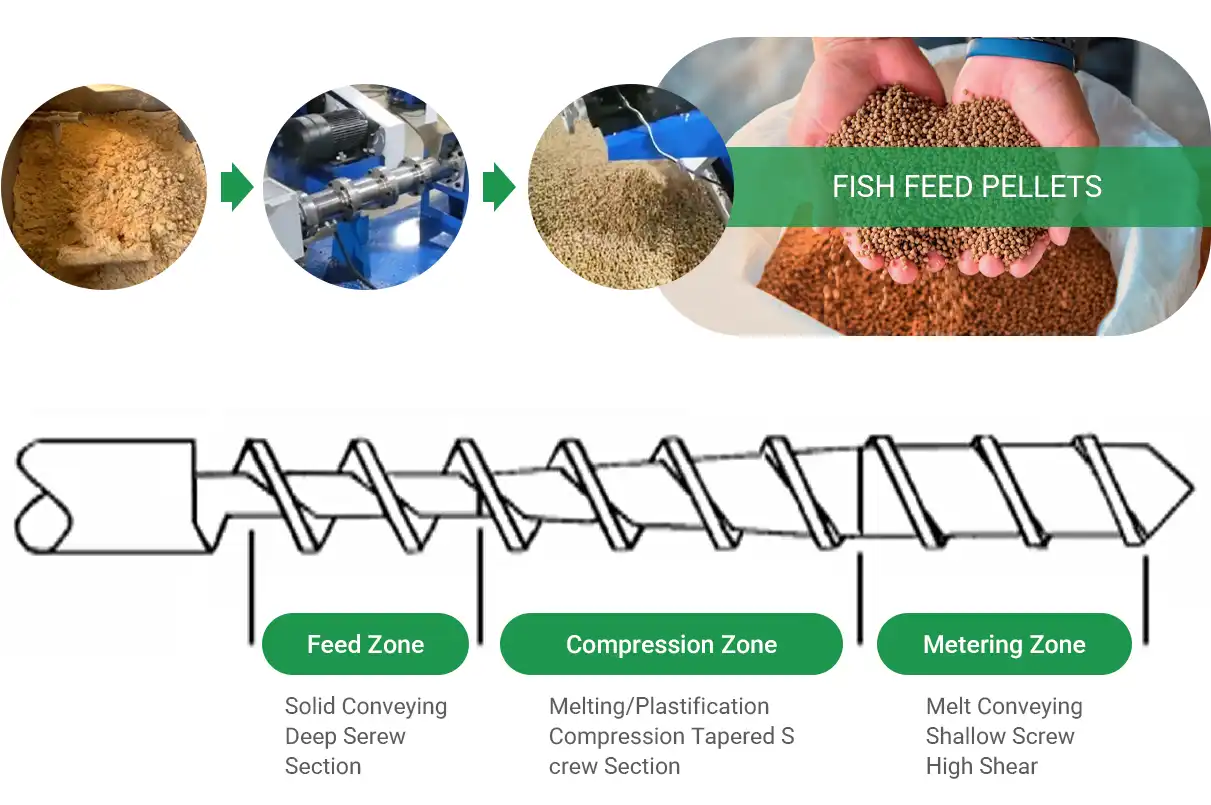

How Does a Fish Feed Pellet Mill Work?

A dry-type fish feed extruder doesn’t rely on steam or external heating. Instead, it uses mechanical friction to heat and cook the raw materials.

- Feeding: Raw ingredients enter through the feed hopper and are pushed forward by a screw.

- Compression and Heating: In the compression zone, friction heats and shears the material into a soft, semi-fluid form.

- Puffing: As the material exits the die, pressure drops suddenly, causing the moisture to vaporize and expand into porous pellets.

(Some models are equipped with electric heating rings or rods to preheat the barrel before startup for better extrusion results.)

Pelletizing Process of the Fish Feed Extruder

-

Raw Material Preparation

Mix rice, corn, starch, and other ingredients in the right ratio. Keep moisture below 18% for best results. -

Feeding

The mixed raw materials are fed into the extruder either manually or via a feeder. -

Pellet Formation

Inside the machine, the materials are cooked and expanded under high temperature, high pressure, and intense friction. A cutter trims the extruded material into uniform pellet lengths. -

Drying and Cooling

The freshly formed pellets are dried and cooled to reduce moisture content. After drying, the moisture level should be no more than 12%. -

Packaging and Storage

Finally, the pellets are sealed and stored in a dry, well-ventilated area to prevent moisture and spoilage.

KAWISE Fish Feed Extruder Machine for Sale

| Model | Capacity (kg/h) | Host power (kw) | Feeding power (kw) | Cutting power (kw) | Machine size (mm) | Weight (kg) |

| KP-40 | 40-60 | 5.5/7.5 | 0.4 | 0.4 | 1200*900*1100 | 300 |

| KP-50 | 60-80 | 7.5 | 0.4 | 0.4 | 1300*950*1150 | 350 |

| KP-60 | 100-150 | 15 | 0.4 | 0.4 | 1350*1000*1200 | 400 |

| KP-70 | 150-200 | 18.5 | 0.4 | 0.4 | 1350*1100*1200 | 460 |

| KP-80 | 200-250 | 22 | 0.55 | 0.55 | 1550*1100*1200 | 550 |

| KP-90 | 250-300 | 30 | 1.1 | 1.5 | 1750*1450*1300 | 800 |

| KP-100 | 300-400 | 37 | 1.1 | 1.5 | 1850*1550*1500 | 950 |

Is the Dry Fish Feed Extruder Right for You?

This machine is a great fit if you:

- Want a machine that’s simple and easy to run.

- Want to keep costs down and get the best value for money.

- Run a small or medium-sized fish or shrimp farm, or make your own fish food pellets.

- Use standard low-fat feed formulas (such as corn, soybean meal, starch) and don’t need to process high-fat or high-protein materials.

(We offer customized solutions for high-fat ingredients or higher output needs. Just let us know what you're looking for.)

Why Us

Why choose KAWISE? Here’s what you’ll get.

- Full range of models: From small-scale to mid-sized production, we’ll match you with the right machine.

- Basic feed formulas provided: We can offer standard fish feed recipes based on your production needs.

- Durable, high-performance parts: The screw and sleeve are made from wear-resistant alloy steel. They’re heat-treated to handle high temperatures and last longer.

- Efficient pelletizing: A longer barrel and refined screw design improve feed expansion and shape. Pellets come out smoother and more uniform.

- Complete service support: We provide full support, including selection, installation, training, and after-sales service. This ensures your machine runs smoothly from day one.

- Competitive pricing: As a direct manufacturer in China, we eliminate middlemen to offer better prices without compromising quality.

Tips for Using a Fish Feed Making Machine

- Control moisture content: For dry-type extruders, keep raw material moisture between 12% and 18%. Too dry makes cooking harder; too wet can cause clogging.

- Test with water before starting: Before preheating, pour in a little water to check if it flows smoothly through the die.

- Preheat before feeding: Wait until the machine reaches a stable temperature before adding raw materials. This helps prevent clogging or misshaped pellets at startup.

- Clean the die and screw regularly: Residual feed can block the die holes over time. Regular cleaning extends the life of the machine.

- Adjust cutter speed and die size: Modify the cutter and die settings based on pellet length and type (floating or sinking) for best results.

Not sure which model to choose? Contact us—we'll help you find the right solution and provide full technical support.