As the demand for eco-friendly livestock feed grows, small feed pellet machines are becoming a popular investment. But why do prices vary so much? In this artical, we’ll talk about 6 key factors that affect the cost, helping you make the right purchase decision.

.webp)

1. Production Capacity and Output Requirements

The higher the output, the higher the price. A machine designed to produce 500 kg/h will cost significantly more than a 50 kg/h model due to larger motors, advanced molds, and automation.

- Model Selection: Choose between small models for small farms and industrial-grade machines for commercial production.

- Customization: Features like automatic pellet size adjustment or multi-material compatibility can increase costs.

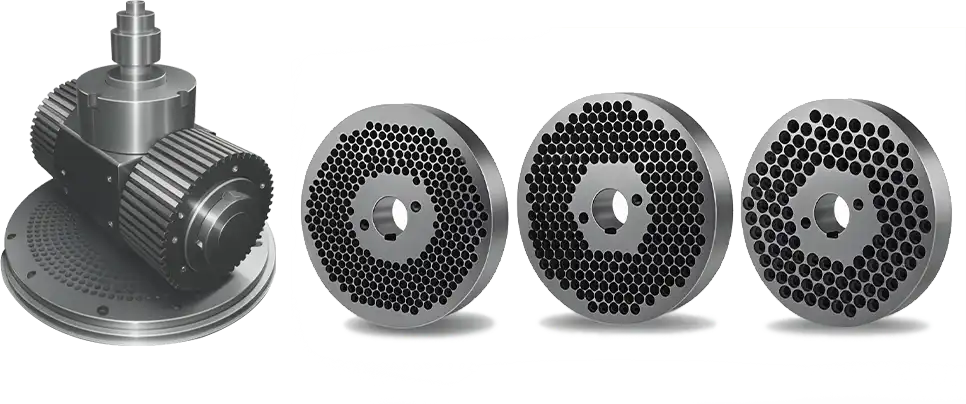

2. Technology & Component Quality

The quality of internal components directly impacts cost and durability.

- Premium Materials: Machines with stainless steel rollers and reinforced screw presses last longer but cost more.

- Smart Features: Models with IoT sensors (for temperature & pressure monitoring) or touchscreen controls tend to be pricier but can reduce labor expenses.

- Warranty Matters: High-end manufacturers typically offer longer warranties, while budget models may only provide basic coverage.

3. Raw Material Compatibility

- Feed Ingredient Types:Machines vary depending on the materials (e.g., grains, fibrous feeds).

- Processing Needs:Specialized machines for tough materials (like straw) cost more.

| Material Type | Machine Cost Impact | Maintenance Needs |

| Soybean Meal | Low | Low |

| Alfalfa Hay | Medium | Medium-High |

| Straw & Fibrous Feed | High | High |

.webp)

4. Brand Reputation & Distribution Channels

Brand selection influence both pricing and after-sales service.

-

Premium vs. Budget Options:

- Some manufacturers charge more due to R&D-backed innovation and strict quality control.

- Cost-effective alternatives may offer similar performance but with simpler designs and fewer automation features.

-

Direct Purchase vs. Dealer Markup:

- Buying directly from the manufacturer can help you save on distributor markups.

5. Production Location and Shipping Costs

Where you buy the machine significantly affects the final price.

- Domestic vs. Imported Machines:Machines from overseas may have lower base prices, but tariffs, freight costs, and import taxes can add to the total expense.

- Offshore Production:Some countries offer lower manufacturing costs, but it’s important to check local compliance standards before purchasing.

6. After-Sales Service and Warranty Period

- After-Sales Support: Machines with long-term warranties and maintenance services may cost more initially, but they can lower long-term repair and failure costs.

- Warranty & Support: Extended warranties and technical support ensure reliable assistance if issues arise, providing long-term peace of mind despite the higher upfront cost.

How to Make the Best Decision Based on Price Factors

- Define your daily output goals and required feed types.

- Compare multiple suppliers and request a detailed cost breakdown.

- Request a trial run to evaluate performance before buying.

When choosing a feed pellet machine, it's important to balance cost, quality, and functionality to make a smart investment. Need the best small feed pellet machine for your business? Contact us today for expert advice and exclusive deals!