A pet's health depends on the quality of its food. Compared to traditional feed, extruded feed is easier to digest, has better taste, and lasts longer in storage. That's why more pet food producers are switching to extruded feed - and a reliable extruder is key to making it.

What Is a Pet Food Extruder?

A pet food extruder uses high heat and pressure to cook and expand raw ingredients into puffed pellets. Inside the chamber, materials are mixed, compressed, and sheared. As they exit the mold, the sudden pressure drop causes them to puff into shape.

Wide Range of Applications

This machine is suitable for producing:

- Dog and cat food

- Fish and shrimp feed

- Bird food

- Livestock and poultry feed

- Floating or sinking pellets for different aquaculture needs

- Bait and feed for lobsters, bullfrogs, etc.

By changing the molds and adjusting the formula, you can make different shapes and densities of feed.

Recommended Feed Formulas

Here are some example formulas for different types of pet food:

| Dog: Chicken meal, cornmeal, soybean meal, fish oil, plant protein, vitamins, minerals. |

| Cat: Chicken meal, cornmeal, rice flour, fish meal, vegetable oil, vitamins, dried vegetables. |

| Bird: Sorghum, cornmeal, wheat flour, sunflower seeds. |

| Rabbit: Hay powder, soybean meal, cornmeal, carrot powder, leafy greens, minerals. |

| Fish: Fish meal, soybean meal, cornmeal, wheat bran, vitamins. |

| Shrimp/Crab: Fish meal, shrimp shell powder, cornmeal, soybean meal, attractants. |

| Lobster/Bullfrog: Silkworm pupae powder, fish meal, soybean meal, shrimp meal, wheat bran. |

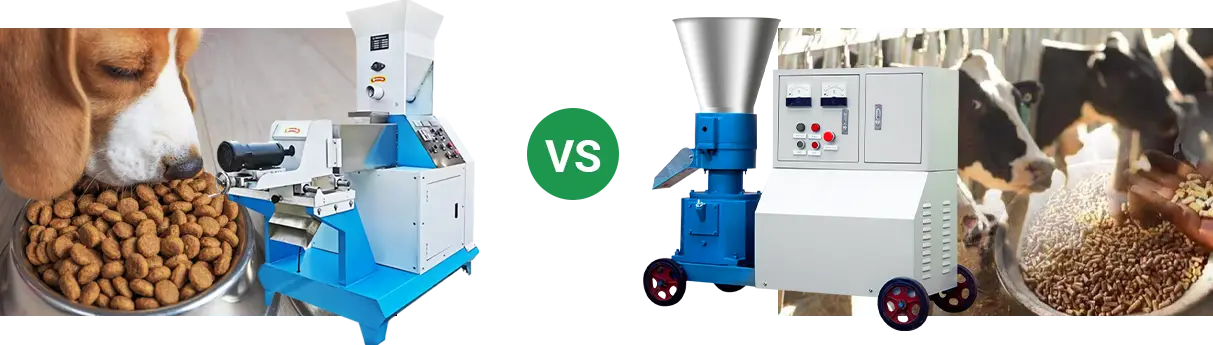

Pellet Extruder Machine vs. Pellet Mill

| Feature | Extruder | Pellet Mill |

| Temperature | High temp (over 100°C) | Medium temp (60–80°C) |

| Texture | Puffed, floating/sinking | Dense, sinking |

| Processing | High-temp expansion | Mechanical compression |

| Energy Use | Higher (heating required) | Lower |

| Texture | Crispy, tasty, digestible | Chewy, suitable for ruminants |

| Size Range | Broadly adjustable; suitable for various animal needs | Relatively fixed; suitable for standardized production |

| Shape | Supports multiple shapes (e.g., round, star, bone) | Primarily cylindrical; limited shape options |

| Applications | Pet food and aquafeed | Poultry and livestock feed |

In short: If you need floating pellets or want to make feed easier to digest, go with an extruder machine. For regular poultry feed, a pellet mill may be more cost-effective.

Benefits of Extruded Feed Mill

- Easier to digest and absorb: High-temperature cooking denatures proteins and breaks down starch, boosting nutrient absorption.

- More palatable: Light, crispy texture and rich aroma make pets more eager to eat.

- Better feed efficiency: Uniform pellets reduce waste and help lower feeding costs.

- Safer and cleaner: Heat kills harmful bugs and helps prevent disease.

- Longer shelf life: Low moisture content prevents mold and makes storage and transport easier.

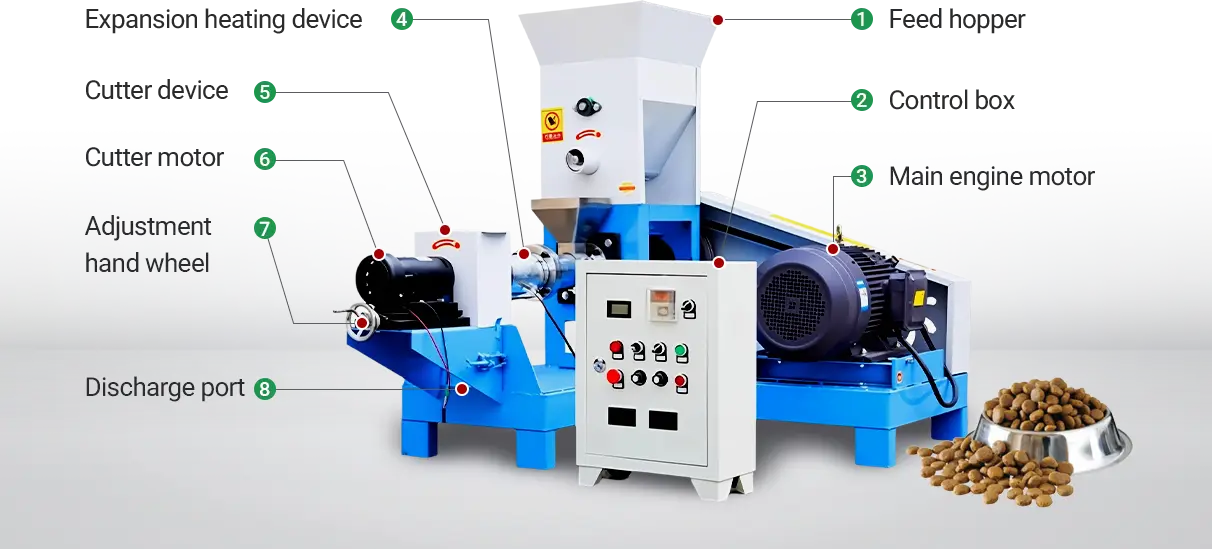

Product Features

- Large Feed Hopper – Holds more, feeds smoother

- Smart Control Panel – Easy operation, built to last

- Pure Copper Motor – Stable and energy-efficient

- High-Speed Heating Chamber – Fast, powerful expansion

- Precision Cutter – Clean cuts, uniform size

Every part is designed to make your work easier-and your pellets better.

Product Specs Overview

| Model | Capacity (kg/h) | Host power (kw) | Feeding power (kw) | Cutting power (kw) | Machine size (mm) |

| KP-40 | 40-60 | 5.5/7.5 | 0.4 | 0.4 | 1200*900*1100 |

| KP-50 | 60-80 | 7.5 | 0.4 | 0.4 | 1300*950*1150 |

| KP-60 | 100-150 | 15 | 0.4 | 0.4 | 1350*1000*1200 |

| KP-70 | 150-200 | 18.5 | 0.4 | 0.4 | 1350*1100*1200 |

| KP-80 | 200-250 | 22 | 0.55 | 0.55 | 1550*1100*1200 |

| KP-90 | 250-300 | 30 | 1.1 | 1.5 | 1750*1450*1300 |

| KP-100 | 300-400 | 37 | 1.1 | 1.5 | 1850*1550*1500 |

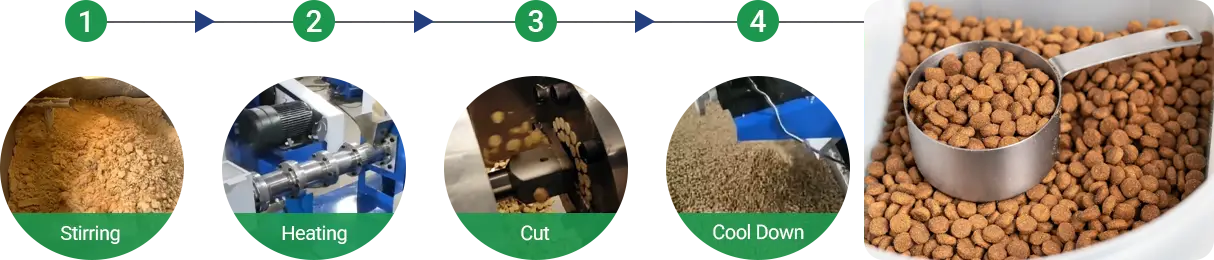

How to Use – Quick 5-Step Guide

Getting started is easy. Just follow these five simple steps:

- Mix your ingredients (add oil, vitamins, nutrients)

- Load into the machine

- Extrude and cut into shape

- Cool naturally or with a cooler

- Bag it, store it, or ship it

Extruder Machine for Sale

We specialize in high-quality pet food extruders that also work for aquaculture feed. Whether for home use or commercial production, we've got you covered.

- Factory-direct pricing

- Multiple models available, from small-scale to industrial

- Custom molds for different shapes and sizes

- Durable materials: Alloy steel parts with long service life

- Fast delivery with minimal waiting time

- Professional support: Reliable after-sales service

Whether you're feeding pets, fish, or livestock, this is the machine that does it all. Get in touch now and get your quote!