What is Corn Stover?

Corn stover is a by-product of corn harvesting, including stalks, leaves, husks, and cobs. For every 1 ton of corn grain, approximately 1 ton of corn stover is produced (corn stover/grain ratio is about 1:1). Corn stover has huge potential as a sustainable biomass energy source.

Top 10 Corn Stover Producing Countries in 2023

| Country | Corn Stover Production (Million Tons) |

| 🇺🇸 United States | 389.7 |

| 🇨🇳 China | 288.8 |

| 🇧🇷 Brazil | 132 |

| 🇦🇷 Argentina | 41.4 |

| 🇮🇳 India | 38.1 |

| 🇺🇦 Ukraine | 31 |

| 🇲🇽 Mexico | 27.5 |

| 🇮🇩 Indonesia | 20 |

| 🇷🇺 Russia | 16.6 |

| 🇿🇦 South Africa | 16.4 |

Source: Top 10 World's Biggest Maize-Producing Countries

How to Produce Corn Stover Pellets?

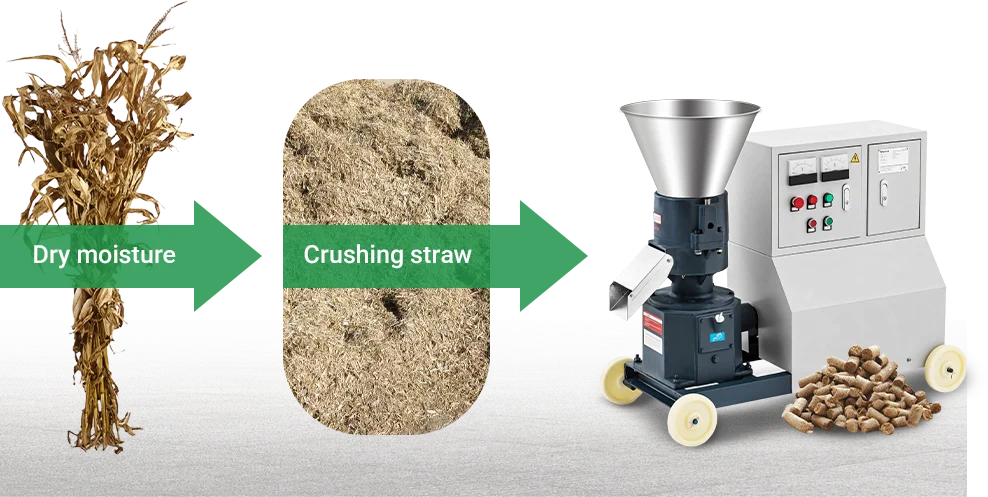

Before pelletization, corn stover must be collected and sun-dried for a few days to reduce moisture content. The pelletizing process consists of the following steps:

- Grinding: Use a hammer mill to grind corn stover into particles smaller than 5mm.

- Pelletizing: Feed the ground material into a corn stover pellet machine, where it is compressed into pellets under high temperature and pressure.

- Cooling & Packaging: Freshly produced pellets must be cooled before being stored or packed for transportation and use.

Corn Stover Pellet Machine Specifications

| Model | Power (kw) | Capacity(kg/h) | Weight (kg) | Roller | Die Hole (mm) |

| KD-200B | 7.5 | 100-150 | 220 | 2 Roller | 2.5/3/4/5/6/8 |

| KD-230B | 11 | 150-220 | 300 | 3 Roller | 2.5/3/4/5/6/8 |

| KD-260B | 15 | 200-300 | 330 | 3 Roller | 2.5/3/4/5/6/8 |

| KD-300B | 22 | 300-450 | 380 | 3/4 Roller | 2.5/3/4/5/6/8 |

| KD-400B | 37 | 550-750 | 500 | 4 Roller | 2.5/3/4/5/6/8 |

Flat Die Corn Stover Pellet Machine: Ideal for small-scale pellet production, allowing users to make pellets at home.

Ring Die Corn Stover Pellet Machine: Suitable for large-scale pellet production.

Our corn stover pellet press is equipped with alloy steel components, ensuring durability, high efficiency, and high output. It also features a long service life and supports continuous production.

Corn Stover Pellet Properties

| Parameter | Value Range |

| Lower Heating Value (LHV) | 16-18 MJ/kg (≈3,800-4,300 kcal/kg) |

| Higher Heating Value (HHV) | 17-19 MJ/kg (≈4,000-4,500 kcal/kg) |

| Pellet Size | Diameter: 6-12mm, Length: 10-25mm |

| Color | Light brown or yellowish-brown (depending on drying process) |

| Density | 1.1-1.3 g/cm3 |

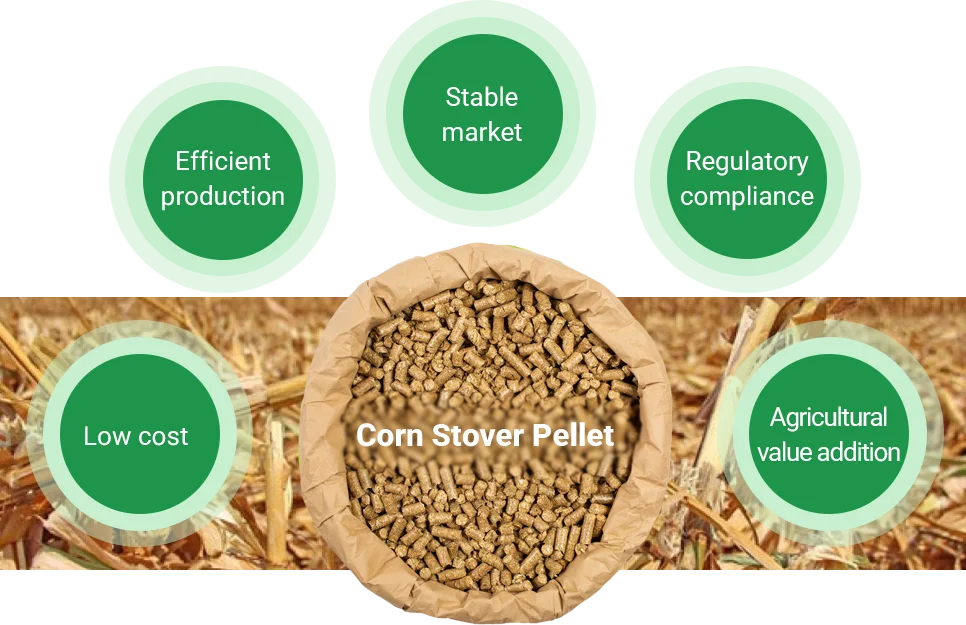

Economic Benefits of Corn Stover Pellets

Due to the abundant and low-cost availability of corn stover, Kawise's client saw huge market potential and modified an existing pellet plant to conduct test production. The company now supplies corn stover pellets to nearby power plants on a stable basis.

- Low-cost raw materials: Corn stover is widely available and cheaper than wood pellets.

- Efficient production: Producing 15,000 tons of pellets annually, meeting long-term power plant demands.

- Stable market: 3-year supply contract with power companies, ensuring profitability.

- Regulatory compliance: Meets renewable energy standards, allowing companies to earn carbon credits.

- Agricultural value addition: Farmers can sell corn stover for extra income, reducing waste.

Basic Information on Corn Stover

Moisture Content of Corn Stover

| Component | Moisture Content (%) |

| Stalks & Leaves | 0.33 |

| Husks | 0.24 |

| Cobs | 0.19 |

Main Composition of Corn Stover as Fuel

| Component | Content (%) |

| Cellulose | 0.38 |

| Hemicellulose | 0.26 |

| Lignin | 0.19 |

📌 Need expert guidance on corn stover pelletizing technology? Contact us for professional support! enquire now

Comparison of Corn Stover Densification Methods

Corn stover has low bulk density, leading to high transportation costs. To solve this, several densification methods are used, including stacking, baling, briquetting, and pelletizing. Pelletizing is the most effective method.

Lignin and water-soluble carbohydrates in corn stover make it easier to pelletize than some other energy crops (such as switchgrass or miscanthus, which have lower lignin content), even without adhesives.

| Method | Density (kg/m3) | Specific Energy (KJ/kg) |

| Stacking | 147.4 | N/A |

| Baling | 160 | 5.76 |

| Briquetting | 463.4 | 415.5 |

| Pelletizing | 603.6 | 262.3 |