As environmental concerns rise and energy demand increases, sawdust pellets is gaining popularity as a renewable resource. Sawdust pellet machines can turn sawdust into clean fuel, feed, and fertilizer. Providing a green and profitable disposal solution for the environment and the economy.

Overview of Sawdust Disposal Methods

Sawdust is a common by-product in agriculture and industry, and its treatment impacts resource efficiency and environmental protection. Here's a comparison of several disposal methods:

| Disposal methods | Usage | Analysis |

| Compost | After degradation, converted into organic heat or electricity | environmentally friendly, but there may be a risk of odor and buildup of harmful substances. |

| Carbonate | Soil improvement | Produce harmful gas (CO), pollute the environment. |

| Incinerate | Fertilizer generating | High energy use and low resource efficiency may release harmful gases. |

| Landfill | —— | as fuel or industrial feedstock |

| Granulate | As fuel or industrial feed stock, filler, animal feed, etc. | Produce environmentally friendly clean energy and broaden the application field of sawdust. |

These methods can all treat sawdust, and while each has its benefits, they also come with potential environmental and health risks. Sawdust pelletizing is the least harmful method and allows for the greatest benefits.

Benefits of Making Sawdust into Pellets

Processing sawdust into pellets is an efficient way to utilize resources. This approach benefits both environmental protection and economic growth.

Environmental Benefits

Reducing Greenhouse Gas Emissions

Sawdust pellets come from plants that absorb CO2. Using these pellets can reduce carbon emissions and supports carbon neutrality.

Replacing Traditional Fuels

Sawdust pellets emit fewer harmful gases (e.g., sulfur dioxide, nitrogen oxides). Compared to coal, it helps to reduce air pollution and improve air quality.

Efficient Resource Use

Sawdust is a by-product of various industries. Turning it into energy by packing it on pallets helps prevent waste and reduce environmental impact.

Economic Benefits

Lower Energy Costs

Wood pellets have a calorific value of 4,400 kcal/kg(Calorific Value Of Wood Pellets). They are a renewable energy source for heating, industrial boilers, and power generation. Using pellets reduces reliance on traditional fuels like coal and natural gas, cutting energy procurement costs.

Increased Value of Sawdust

Sawdust transforms from waste to high-value products like biomass fuel, feed, and soil amendments. This boosts its economic value and opens new markets.

Reduced Waste Disposal Costs

Traditional disposal methods, like dumping and burning waste, damage the environment and add extra costs.Granulating sawdust turns it into valuable products, reducing waste management costs and making disposal easier.

Market Demand Growth

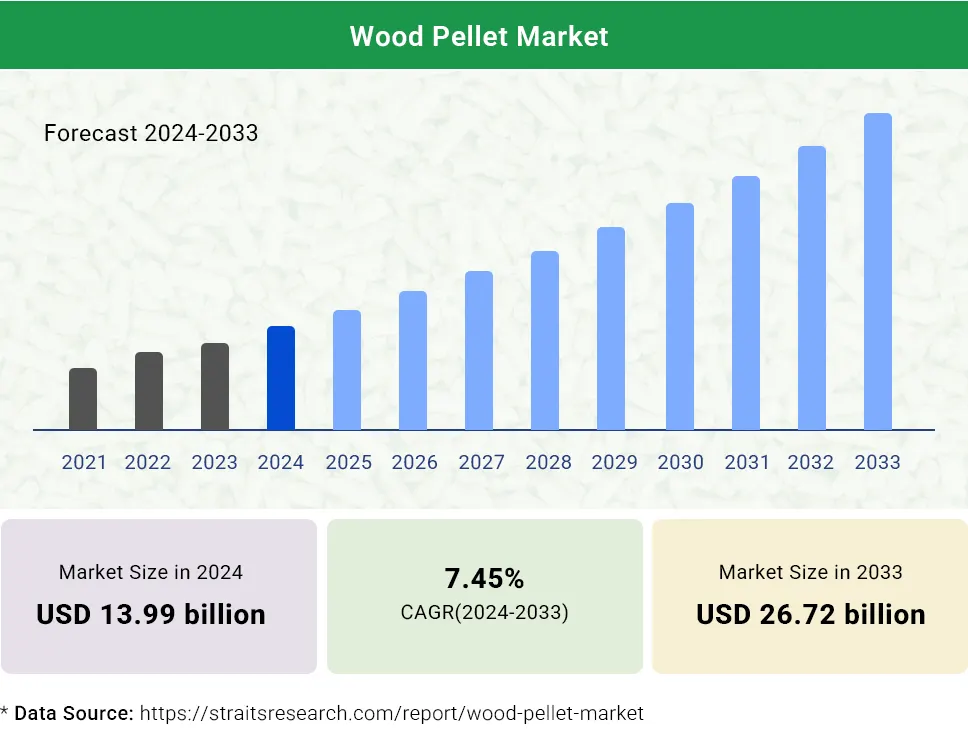

As global focus on renewable energy grows, so does the demand for wood pellets. The research shows that the market grow at a rate of 7.45;annually.

The Specific Process of Making Sawdust Pellets

Required Equipment

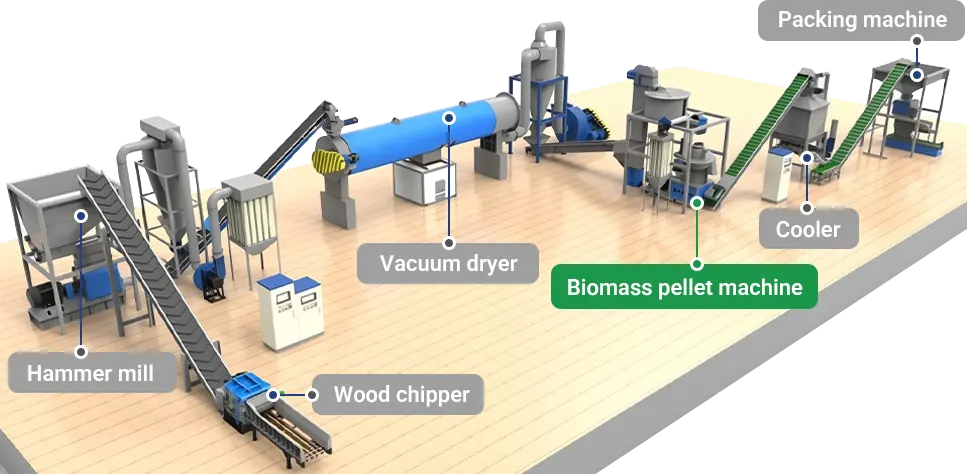

To make sawdust pellets, you need equipment like grinders, dryers, sawdust pellet machine, coolers, and packaging machines. While cutting machines, vibrating screens, and conveyors aren't essential, they can boost efficiency and pellet quality.

Specific Operation Process of Sawdust Pellet Machine

The sawdust pellet machine uses high heat and pressure to compress raw materials into compact pellets.

- Raw material preparation: Collect dry sawdust and remove impurities.

- Drying: Reduce the moisture content to 10-15%.

- Smashing: Crush wood chips into smaller particles.

- Pelletizing: Compress the sawdust into pellets.

- Cooling and cutting:Cool and cut them to the appropriate size.

- Storage and packaging:Keep the pellets in a dry area and package them accordingly.

Alternative Sawdust Pellets Uses

Wood pellets have a wide range of applications in energy, agriculture, industry, horticulture and other fields, providing sustainable alternative energy and raw materials:

| Application Area | Use |

| Biomass fuel | Used for home heating, industrial boilers and power generation as an environmentally friendly alternative fuel. |

| Feed | Used as an additive for animal feed to increase cellulose, especially for herbivorous animals. |

| Horticulture and soil improvement | Helps improve soil, increase drainage, and retain moisture. It also prevents impurities when used as mulch. |

| Drug industry | Sometimes used as a filler material to provide structure and stability, especially in natural medicinal preparations. |

| Animal bedding | Used in aquaculture to keep the environment dry and hygienic and reduce the spread of disease. |

| Water treatment | As a filter material, remove impurities and harmful substances from water. |

| Paper and wood processing | As raw material for producing recycled paper or other wood boards. |

Possible Challenges and Solutions

Sawdust Pelletizing: Challenges and Solutions

Sawdust pelletizing is an efficient and eco-friendly process, but it comes with several challenges. Here’s an overview of the issues and their solutions:

| Challenge | Problem | Solution |

| Raw Material Quality | Uneven moisture, impurities, and size affect pellet quality. | Remove impurities and control moisture levels. |

| Equipment Costs and Maintenance | High costs and frequent repairs. | Choose efficient machines and do regular check-ups. |

| Energy Consumption | Pellet making uses a lot of energy. | Save energy with better processes and renewable sources. |

| Market Competition & Price Fluctuations | Changing raw material prices and tough competition. | Use different raw materials and lock in prices with contracts. |

| Environmental Impact (Dust and Noise) | Dust and noise during production. | Install dust removal systems and reduce noise pollution. |

By sloving these problems, wood pellet processing can become more efficient, eco-friendly, and economically beneficial.

Wood pellets are eco-friendly and cost-effective, can used in many industries. Whether you are a carpenter, a farmer, or an individual requiring wood chip disposal management. Turning sawdust into pellets is the best disposal method for you. In this way you can save money, reduce pollution, and boost efficiency in the long run.