Choosing between a flat die and a ring die pellet mill? If you're planning for home use or small-scale production, knowing the difference can help you pick the one that truly fits your needs.

Definition and Characteristics of Flat Die Pellet Mills

A flat die is a metal plate with small holes-either round or rectangular. It's often used in small-scale feed production and usually makes softer, less dense pellets.

Working Principle of Flat Die Pellet Mills

The material drops in through the feed chute and spreads out over the flat die. As the rollers move across the surface, they press the material through the holes, forming compact pellets.

Advantages and Disadvantages of Flat Die Pellet Mills

| Advantages | Disadvantages |

| Budget-friendly : A great choice for small to mid-sized production setups. | Faster wear and tear : Rollers and dies need frequent replacement. |

| User-friendly : Simple to run and easy to maintain, even for beginners. | Softer pellets : Less dense and may not hold up well during storage or transport. |

| Great for small batches : Easy to adjust when switching raw materials or formulas. | Struggles with sticky or hot materials : Can clog or overheat more easily. |

| Easy cleanup : Open design makes it simple to clean and service. | Higher energy use : Uses more energy than ring die pellet mills for the same output. |

| Compact and portable : Doesn't take up much space and can be moved around easily. | Can't handle hard materials : Tough inputs may cause damage over time. |

| See it in action : The process is easy to monitor and troubleshoot. | Limited capacity : Built for low-volume production, not industrial-scale. |

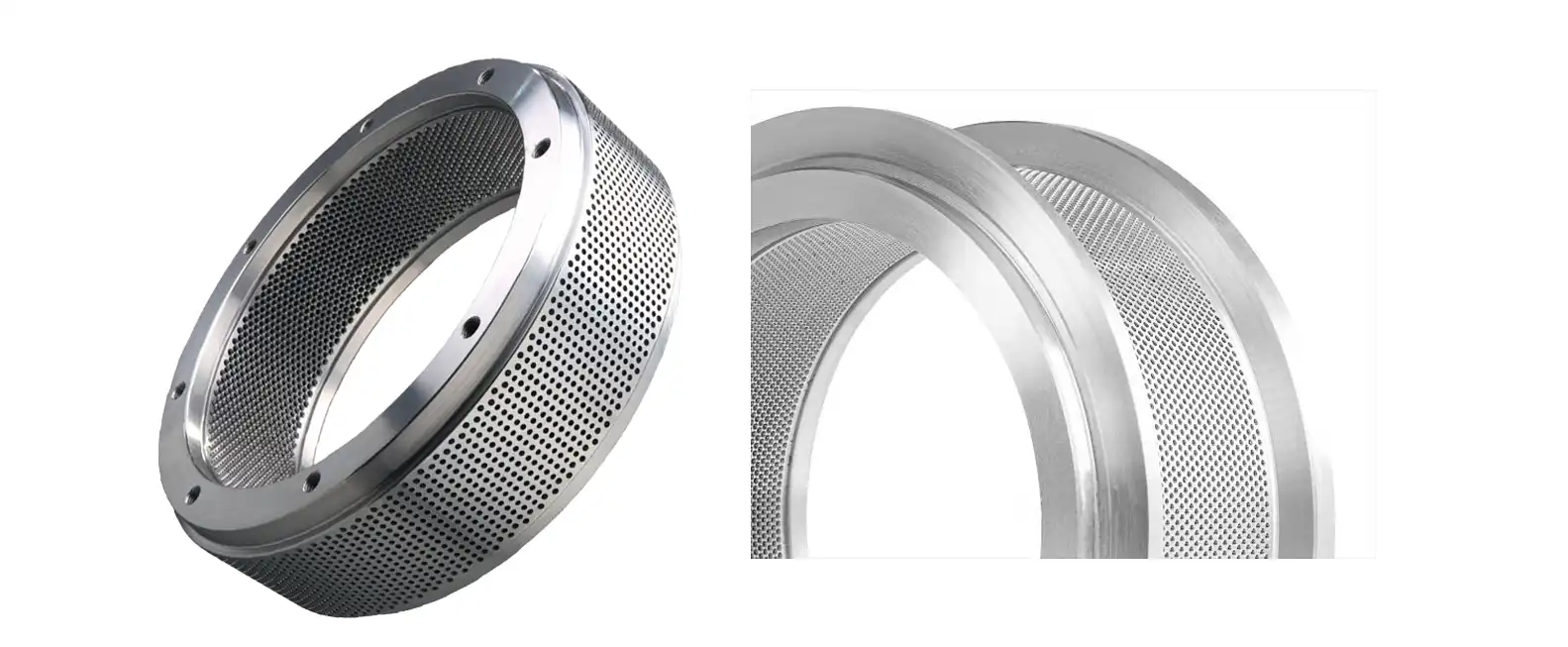

Definition and Characteristics of Ring Die Pellet Mills

A ring die is a circular die with numerous small holes on its surface. Raw materials are compressed through these holes to form pellets. Ring dies are typically used in large-scale production, producing more uniform and denser pellets.

Working Principle of Ring Die Pellet Mills

Once the material is mixed and conditioned, it enters through the feed chute. Inside, rotating rollers press it firmly against the inner wall of the ring die, pushing it through tiny holes to form long, dense strands. A sharp blade cuts them into uniform pellets, which drop out through the outlet.

Advantages and Disadvantages of Ring Die Pellet Mills

| Advantages | Disadvantages |

| High efficiency : Perfect for nonstop or large-scale production where volume matters. | Higher upfront cost : Buying and installing one of these isn't cheap. |

| Energy Efficient: Uses energy effectively and distributes it evenly. | Takes up room : You'll need dedicated space for setup and operation. |

| Handles diverse materials : Great with varying sizes and raw materials. | Not for beginners : These machines work best in experienced hands. |

| Consistent pellet quality : Produces dense, uniform pellets. | Maintenance takes work : Swapping out parts like rollers or dies can take time and tools. |

| Great for high-output jobs : Ideal for factories or commercial operations. | Too much for small setups : Not practical if you're running a low-volume or mobile system. |

| Lower cost per ton : Consumes less energy per unit compared to flat die pellet mills. | Harder to monitor : Since the pressing happens behind a cover, spotting issues isn't as easy. |

How to Choose the Right Pellet Mill for Your Business

Here are a few questions to guide your decision-making.

- Figure out your production needs: Are you making 100 kg a day-or several tons? The right machine depends a lot on how much you plan to produce.

- Think about what you're feeding into it: Is it soft animal feed, hardwood chips, or something wetter like fertilizer? Some machines handle certain materials better than others.

- Set a realistic budget: Flat die mills are more affordable up front, but ring die models tend to save more in the long run if you're producing a lot.

- Check your available space: Ring die machines take up more room and usually need a permanent setup. Flat die mills are more compact and easier to move around.

- Be honest about your experience level: Flat die mills are beginner-friendly. Ring die machines? Better if you've got some hands-on experience or trained staff.

Which One Should You Choose?

- Flat Die Pellet Mill: If you're after something affordable and easy to use, a flat die pellet mill could be exactly what you need. It's perfect for smaller operations, DIY animal feed, or small-scale feed production. With its compact, portable design and easy maintenance, it's the ideal choice for farmers and hobbyists.

- Ring Die Pellet Mill:If you're producing at scale and need a robust, industrial-grade machine, the ring die pellet mill is your best bet. This machine powers high-volume commercial feed production, wood pellet manufacturing, and biomass pellet production. It delivers efficiency, consistency, and durability, making it perfect for long hours of continuous operation.

Not sure which pellet mill suits your needs? Get in touch for expert advice, and we'll help you find the right one for you!