In today's industrial landscape, pellet mills play a crucial role in various sectors such as agriculture, animal feed production, and biomass energy. As a pellet mill manufacturer, we are committed to providing high efficiency and energy saving pellet mill equipment for our clients.

When choosing a pellet machines, it's essential to consider not only its technical performance but also its long term reliability and operational cost. This blog will help you understand how to select the right pellet mill for your needs, improve production efficiency, and reduce maintenance costs.

1. Working Principle of Pellet Mills

A pellet mill, as the name suggests, is a machine used to compress raw materials into pellet-shaped products. The basic working principle involves feeding the raw material through a die, where it's compressed under high pressure to form pellets. Depending on the application, pellet mills can produce various types of pellets, including animal feed pellets, biomass pellets, and fertilizer pellets.

2. Key Factors to Consider When Choosing a Pellet Mill

As a pellet mill manufacturer, we recommend the following key factors when selecting a pellet mill:

a. Pellet Mill Capacity

It's important to choose a pellet mill that matches your production needs in terms of capacity. Pellet mchine capacity is typically measured by the weight of pellets produced per hour. Selecting the right capacity ensures the equipment runs efficiently and avoids resource wastage.

b. Durability and Stability of the Equipment

Pellet mills endure significant wear and tear during long hours of operation. Choosing equipment that offers high durability, and stability is essential to minimize downtime and maintenance costs. Opting for well known brands that provide robust pellet mills can help ensure the equipment performs reliably under heavy workloads.

c. Energy Efficiency

With the rising cost of energy, energy efficiency is a critical factor in equipment selection. High efficiency pellet mills not only reduce energy consumption but also provide better economic returns for businesses. Choosing equipment with advanced energy saving technologies will improve overall production efficiency and lower operational costs.

d. Pellet Quality

The quality of the final pellets is directly linked to the competitiveness of the product in the market. Pellet mills that produce uniform, high quality pellets can significantly improve product quality and meet market demands.

3. Applications of Pellet Mills

Pellet mills are used across various industries. Below are some of the key applications:

a. Animal Feed Production

In the animal feed industry, animal pellet machines are used to process raw materials like corn, wheat bran, soybean meal, etc., into high quality animal feed pellets. Pelletized feed not only enhances digestibility for animals but also improves the efficiency of livestock farming.

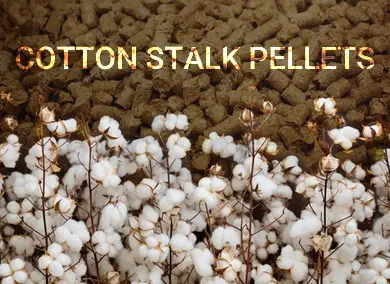

b. Biomass Energy

Biomass pellets produce from agricultural and forestry waste, are a renewable energy source used in home heating, industrial boilers, and power plants. Biomass pellets are an eco friendly alternative to traditional fossil fuels, helping to reduce energy consumption and greenhouse gas emissions.

c. Fertilizer Production

Fertilizer Pellet machines are widely used in the fertilizer industry to produce uniform fertilizer pellets, ensuring that crops receive the right amount of nutrients. Pelletized fertilizers are easier to handle and apply, making them more efficient for agricultural use.

.webp)

Choose pellet mill from a reliable manufacturer with strong technical expertise and extensive experience is key to ensuring high quality equipment and optimal production efficiency. We are committed to providing top notch, customizable pellet mill solutions that help you stay ahead in the competitive market.

If you have any questions about pellet mills or would like to learn more about our products, please feel free to contact our customer service team. We are here to help!