Is the pile of wood scraps, rice husks, or other waste taking up space and hard to clean? Are high heating and boiler fuel costs in winter becoming unbearable? With a wood pellet maker machine, you can turn these waste materials into efficient fuel, solving these issues and cutting your energy costs.

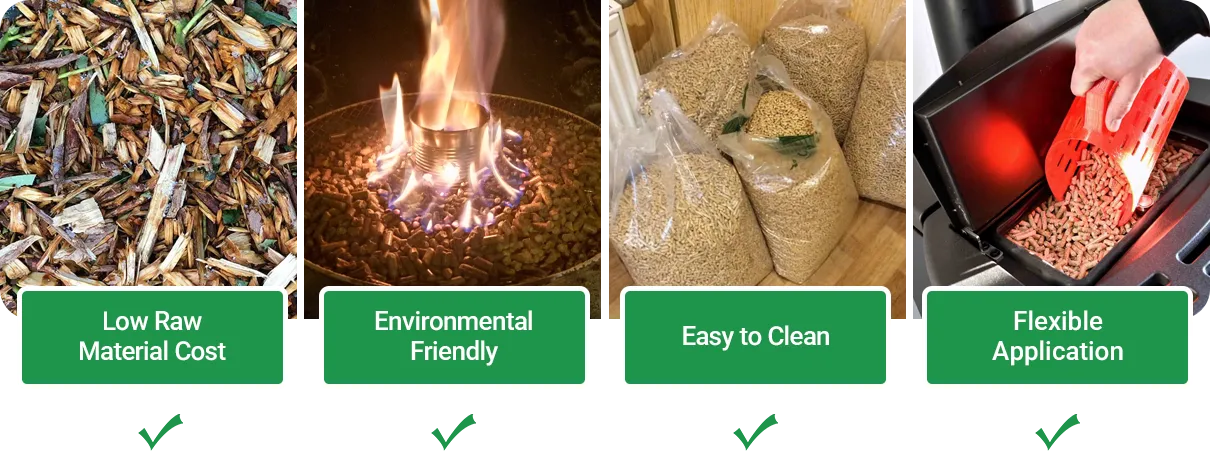

Why You Should Make Your Own Pellet Fuel

- Save money: Sawdust, rice husks, and other waste are cheap and easy to find, cutting down on your heating and energy costs.

- Efficient heating: Pellets burn at 4500 kcal/kg, with minimal smoke and emissions that meet environmental standards.

- Eco-friendly: Turn waste into useful fuel, reducing waste buildup and making disposal easier.

- Flexible use: Sawdust pellets work for home heating, boilers, livestock warming, and more.

Afraid making sawdust pellets is too complicated? Don't worry! With sawdust pellet machine, the process is simple and automatic.

Sawdust Pellet Machine – Easily Make High-Efficiency Fuel

Our high-performance pellet machine is designed for small to medium-scale production. It's reliable, durable, and simple to operate—helping you save time and effort while achieving great results

Pellet Production Process

- Raw Material Preparation: Crush raw materials to ≤5mm and ensure moisture content is 12%-18%

- Feeding: Load the material evenly into the machine.

- Extrusion and Shaping: The roller presses the material into pellet shapes under high pressure.

- Cutting: The cutter trims the pellets to a uniform size.

- Cooling and Screening: Pellets cool down and are ready for use or storage.

Tip: If you don't have a moisture meter, just take a handful of sawdust. If it feels slightly damp but not sticky, it's ready to use.

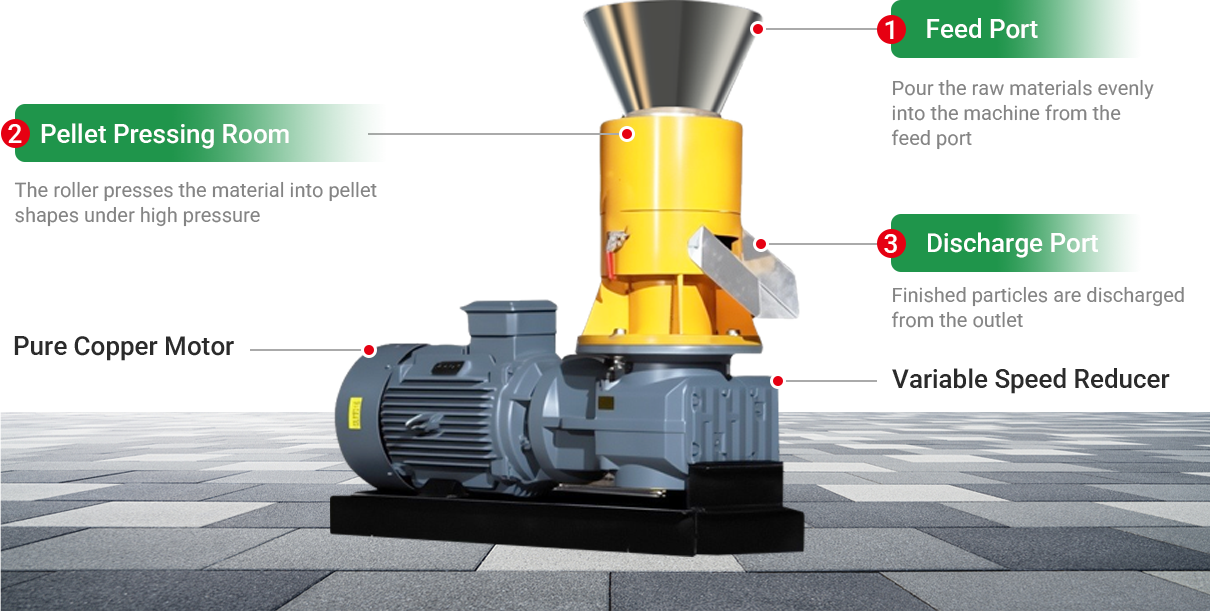

Product Structure and Details

| Mold | Made of durable alloy steel and ensures solid pellets. |

| Roller | Thick and wear-resistant, built to last. |

| Pure Copper Motor | Stable with quick heat dissipation. |

| Hopper | Large opening for easy, spill-free loading. |

| Discharge Outlet | Smooth flow, no jams or sticking. |

| Variable Speed Gearbox | Smooth, efficient, quiet operation. |

| Reinforced Base | Sturdy design for stable, secure operation. |

Easy Operation and Maintenance

- Use Friendly: One person can easily manage the entire process.

- Quick Mold Change: Easily switch molds to adjust pellet size.

- Durable Parts: Long-lasting components that lower maintenance costs.

- Overload Protection: Prevents problems and damage for easy, worry-free use.

Works with a Variety of Materials

This machine can process a variety of biomass materials, including:

| Wood materials | Sawdust, wood shavings, bamboo dust, coconut shell powder, etc. |

| Crop waste | Rice husks, corn stalks, wheat straw, peanut shells, cotton stalks, etc. |

| Fibrous materials | Hemp stalks, palm fibers, sugarcane waste, etc. |

| Mixed materials | A blend of different materials to improve burning efficiency. |

Reminder: To get the best pellets, keep the raw material under 5mm in size and moisture between 12% and 18%.

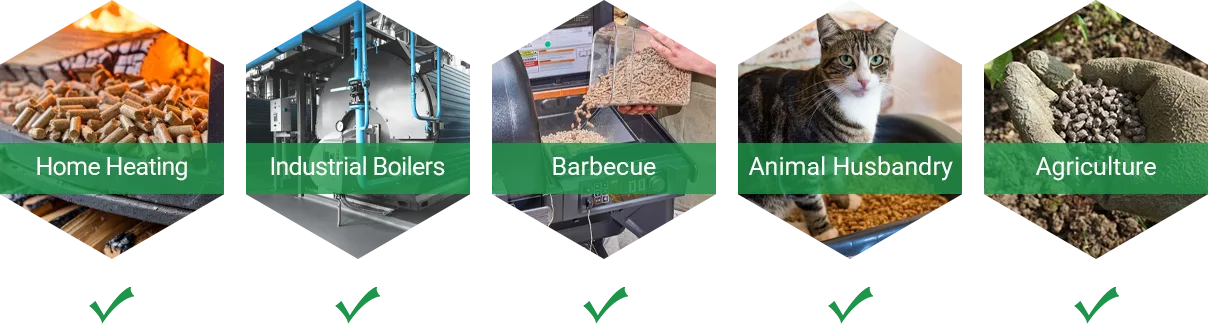

Versatile Applications for Multiple Needs

Wood pellets for heating, industrial boilers, agriculture, or livestock farming. Whatever your need, the wood pellet mill meets them all efficiently.

Comparison of Sawdust Pellets with Common Fuels

Here's a comparison of sawdust pellets and common fuels:

| Fuel Type | Sawdust Pellets | Coal | Natural Gas |

| Calorific Value | 3200-4500 kcal/kg | 5000-6500 kcal/kg | 8500-9000 kcal/Nm³ |

| Ash Content | ≤1.5%, low ash | 10%-20%, high ash | None |

| Emissions | Low smoke, low dust | Heavy smoke, strong odor | Clean emissions |

| Environmental Impact | Renewable biomass | High pollution, high carbon emissions | Clean energy |

| Cost of Use | Low, easy to source | Moderate, fluctuates | High, dependent on gas lines |

Wood fuel pellets have a lower heat value than coal, but they burn cleaner and produce less ash. They are easier to source and offer a more cost-effective, eco-friendly option.

Wood Pellet Machine for Sale

We've been in the pellet machine industry for years, understanding your needs. Our machines come in different models and can be customized for quick production and steady profits.

Model Specifications

| Model | Power (kw) | Capacity (kg/h) | Total Weight (kg) |

| KB-250 | 15 | 100-200 | 400 |

| KB-300 | 22 | 200-300 | 800 |

| KB-350 | 30 | 300-400 | 900 |

| KB-400 | 37 | 400-600 | 1000 |

| KB-450 | 45 | 600-800 | 1500 |

| KB-550 | 55 | 700-1000 | 1800 |

We prioritize each customer's experience, offering one-stop after-sales service to make your entire process hassle-free. Additionally, we provide complete biomass pellet production line solutions to meet all your needs.

-For more information, feel free to contact us for a customized plan!