Wood pellet machines compress materials such as sawdust and wood chips into pellets. They are essential for biomass fuel production.

The KAWISE wood pellet machine has a ring die structure, ensuring reliable long-term operation. Its efficient compression process results in high-quality pellet formation. The machine's compatibility with various wood materials improves resource efficiency.

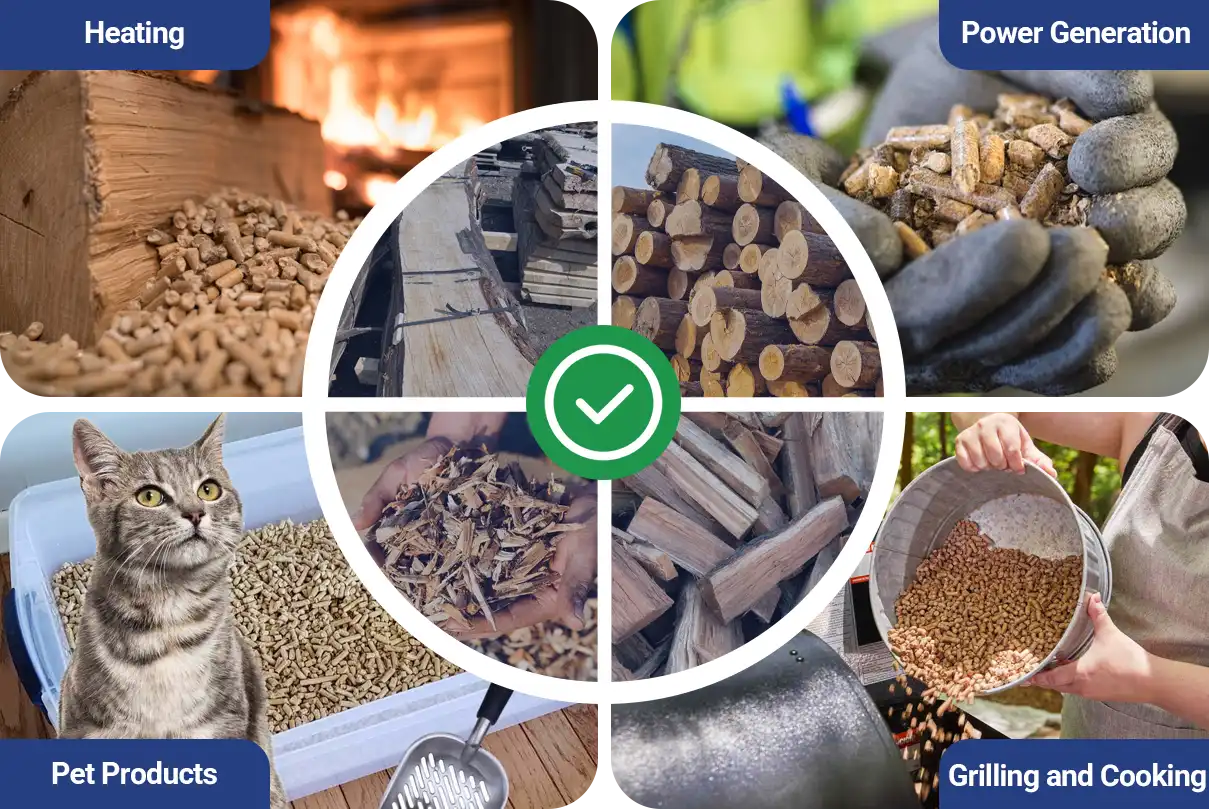

Applications of Wood Pellet Machines

- Heating: Wood pellets can replace traditional fuels like coal, providing clean heating for homes and factories.

- Power Generation: Wood pellets are used as fuel in biomass power plants, reducing dependence on fossil fuels.

- Eco-friendly Pet Products: Pellets made from biodegradable materials like sawdust and bamboo chips are perfect for pet products (e.g., cat litter). They meet the needs of households and pet stores.

- Grilling & Cooking: Food-grade hardwood pellets, such as oak and cherry wood, provide steady heat and a natural wood aroma. They are ideal for home use and the restaurant industry.

KAWISE Ring Die Wood Pellet Machines for Sale

Below are the different models of our wood pellet press machines and their technical specifications.

| Model | Power (kw) | Capacity(t/h) | Weight (t) | Pellet Size (mm) | Die Diameter (mm) |

| KH-450 | 75 | 0.7-1 | 4 | 4-12 | 450 |

| KH-560 | 90 | 1-1.5 | 6.5 | 4-12 | 560 |

| KH-680 | 160 | 1.5-2.5 | 8.5 | 4-12 | 680 |

| KH-850 | 220 | 2-3.5 | 12.6 | 4-12 | 850 |

| KH-880 | 315 | 3.5-4.5 | 14.5 | 4-12 | 880 |

KAWISE Biomass Wood Pellet Machine Technical Features

As an industry-leading wood pellet machine maker, the core technical features of our ring die wood pellet press include:

- The feeder uses a variable frequency motor to prevent clogging and ensure smooth feeding.

- The main shaft system features a dual-support structure, preventing shaft wobbling and providing greater die pressure.

- We improve the strength of key components by enhancing materials and heat treatment processes. This ensures the machine meets the requirements for wood pellet formation.

- The drum uses air cooling to effectively reduce bearing temperature and extend service life. Compared to water cooling, it conserves water and is more energy-efficient.

- The main shaft and roller bearings are equipped with temperature sensors to monitor their working condition.

- The stainless steel ring die, available in various hole sizes, ensures long service life, high pellet density, and smooth surfaces.

- The machine features an advanced compensation-type serpentine spring coupling, which is compact, safe, low-noise, and reliable.

- The main drive uses a high-precision gear transmission system. It provides more power and stable operation compared to traditional belt drives, increasing production capacity.

- The equipment includes safety features such as strong magnetic and overload protection, ensuring reliability and safety during operation.

- The equipment is equipped with an automatic lubrication system (optional) and mold and roller lifting devices. These features improve operational convenience and energy efficiency.

How Does the Ring Die Wood Pellet Machine Work?

When the machine operates, the material is fed into the compression chamber by the feeder. The pressure rollers, driven by the main shaft, roll along the inner wall of the ring die. They continuously press the material into the die holes.

Under high temperature and pressure, the material is compressed and shaped inside the die holes, then extruded out from the holes. The formed pellets are then cut to the desired length by a cutter and fall into the discharge port, completing the pelletizing process.

Advantages of the Ring Die Wood Pellet Mill

In wood pellet production, the ring die structure enjoys wider adoption than flat die machines. Its key advantages include:

- Better Pelletizing Ability: It can handle a wide range of biomass materials, especially hardwoods like palm fiber.

- Higher Quality: Due to higher pressure, the ring die pellet machine produces pellets with higher density and smoother surfaces.

- Higher Output: The ring die pellet machine has a larger production capacity, making it more suitable for industrial-scale production.

- More Stable Continuous Operation: The ring die structure runs smoothly and is ideal for long hours of high-load operation, making it a better fit for medium to large production lines.

The Impact of Raw Material Selection on Pellet Quality and Yield

In wood pellet production, the choice of raw materials significantly affects both the yield and quality of the pellets. The main influencing factors include:

- Type: Different types of raw materials can result in varying quantities of wood pellets. For example, softwood produces a notably higher output than hardwood of the same weight.

- Properties: Generally, powdery materials with fibrous content are more suitable for biomass wood pellet machine. However, if all the raw materials are in powder form, it may hinder the pelletizing process.

- Unit Weight: Unit weight refers to the weight per unit volume. In general, the higher the unit weight, the higher the output of the biomass pellet press.

- Fineness: Raw materials with a higher fineness can absorb steam more quickly, which helps improve production stability and yield. However, fineness needs to be controlled, as excessively fine materials can lead to poor pellet quality or increased wear.

- Moisture Content: The moisture content of raw materials has a significant impact on the production process. Excessive moisture can lead to insufficient steam addition, affecting the temperature rise and consequently reducing the pellet yield.

Operating Requirements for the Ring Die Wood Pellet Machine

- Operating Temperature: The machine should be installed indoors, with an ambient temperature between 5-40°C.

- Voltage: The operating voltage of the wood pellet machine should be stable, with an allowable deviation of less than ±5%.

- Raw Material Moisture: Ensure the moisture content of the raw materials entering the machine is less than 17%.

- Raw Material Size: The raw materials should be less than 5mm in size.

- Ventilation: The operating area of the equipment should be well-ventilated to prevent overheating.

We hope you find the right partner to support your business growth.

If you have any questions or want to learn more about ring die pellet mill for wood, feel free to contact us!